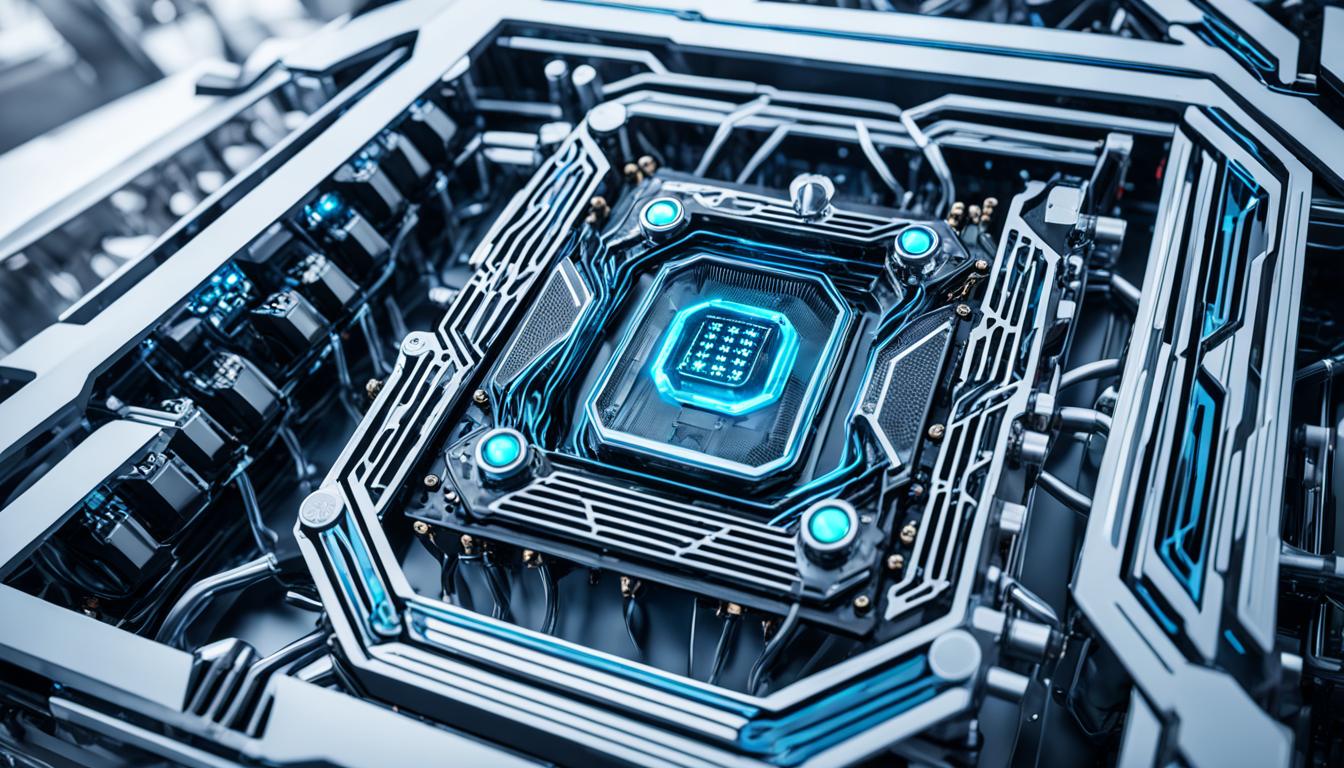

As businesses across industries embrace artificial intelligence (AI) to enhance their offerings, the demand for efficient AI hardware continues to rise. AI technology, with its processing power and bandwidth requirements, poses unique challenges in thermal management. Ensuring optimal performance while managing excessive waste heat is vital for reliability and longevity.

Customizable cooling solutions are essential to meet the diverse needs of different AI applications. Thermal management must be tailored to address the specific cooling requirements of industries such as eMobility and self-driving cars, where AI plays a critical role in optimizing battery cycles and ensuring road safety.

Key Takeaways:

- Thermal management is vital for optimal performance and reliability of AI hardware.

- AI hardware’s processing power and bandwidth pose challenges in managing waste heat.

- Customizable cooling solutions are necessary to meet industry-specific requirements.

- eMobility and self-driving cars rely on AI for optimizing battery cycles and improving road safety.

- Efficient thermal management ensures the longevity of AI hardware.

Growing Artificial Intelligence Applications

Artificial Intelligence (AI) is revolutionizing various industries, including the automotive sector. The integration of AI in eMobility and self-driving cars has led to significant advancements in efficiency, safety, and sustainability.

In eMobility, AI plays a crucial role in optimizing the charging and discharge cycles of batteries. By analyzing data and making real-time decisions, AI algorithms improve energy efficiency and extend the range of electric vehicles. This technology enables users to maximize their driving experience and minimize their environmental impact.

Another significant application of AI in the automotive industry is Advanced Driver Assist Systems (ADAS) in self-driving cars. ADAS systems leverage AI algorithms to analyze data from various sensors, such as cameras and radars. These systems can optimize driving paths, detect obstacles, and make informed decisions based on real-time traffic conditions, ensuring the safety and smooth operation of self-driving vehicles.

The use of AI in the automotive industry has ushered in a new era of intelligent transportation. Self-driving cars equipped with AI capabilities have the potential to reduce accidents and traffic congestion while improving overall road safety. Additionally, AI-driven optimizations can minimize energy consumption and emissions, contributing to a greener and more sustainable future.

With the continued advancement of AI technology, we can expect to see further developments and applications in the automotive industry. From enhancing the user experience in electric vehicles to enabling fully autonomous driving, AI will continue to shape the future of transportation.

The Role of Thermal Management in Artificial Intelligence (AI)

As AI hardware becomes more power-hungry and complex, the need for efficient cooling solutions becomes crucial. Specialized processors like graphics processing units (GPUs) are widely adopted in the AI community but generate excessive waste heat. **Thermal management** solutions are necessary to manage the temperature of AI processors and prevent performance degradation or system failure.

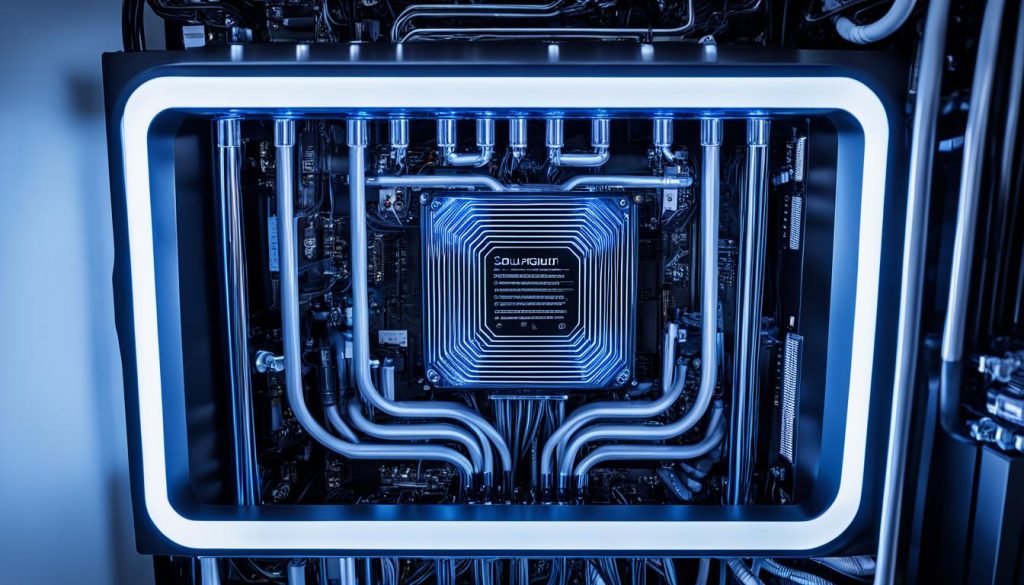

**Liquid cooling** is a promising solution for AI hardware, as it provides higher cooling capacity than air cooling, especially for mobile AI systems with small form factors and low power consumption. With liquid cooling, heat is efficiently transferred away from the AI processors, dissipating it through a liquid coolant circulating within the system. This method ensures effective temperature regulation and allows AI hardware to maintain peak performance even under demanding computational tasks.

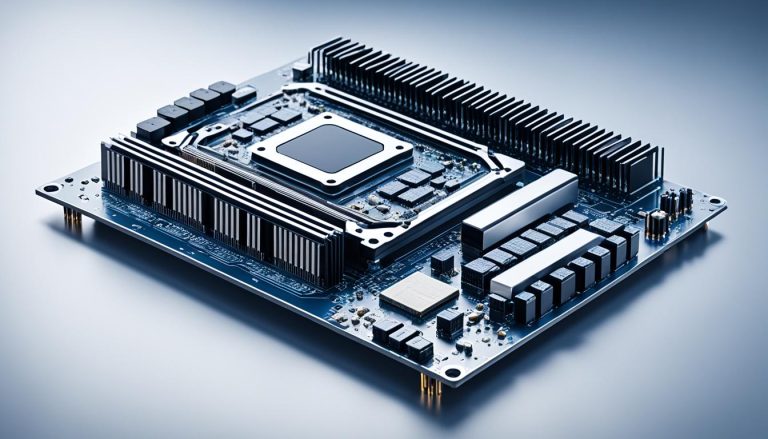

In addition to liquid cooling, other **cooling solutions** such as **heat sinks** and **heat pipes** are also commonly used in thermal management. Heat sinks are designed to absorb and dissipate excess heat, while heat pipes, which utilize phase change and capillary action, efficiently transfer heat away from the heat source. These cooling technologies, combined with efficient liquid cooling systems, enable AI hardware to operate at optimal temperatures and deliver consistent performance.

Efficient thermal management in AI hardware extends the lifespan of **chips** and enhances their overall reliability. By keeping the temperature within an acceptable range, thermal management solutions prevent thermal-induced stress and reduce the risk of premature chip failure. This is especially important in AI applications where continuous processing power is essential for accurate data analysis and complex decision making.

When it comes to AI, thermal management is not just about ensuring proper functioning of the hardware, but also about optimizing **AI performance**. High temperatures can negatively impact computational efficiency, leading to decreased processing speeds and potential errors in AI algorithms. By implementing effective thermal management solutions, AI systems can run at optimum temperatures, maximizing their processing power and accuracy.

Thermal management plays a significant role in AI hardware, keeping the temperature of processors within optimal limits to ensure consistent performance. It enables AI systems to handle the computational demands of complex algorithms while maintaining reliability and longevity.

Customizing Thermal Management for Specific AI Applications

When it comes to thermal management in AI applications, a one-size-fits-all approach is not sufficient. Each AI application has unique cooling requirements that need to be tailored for optimal performance and reliability. Let’s take a closer look at some specific AI applications and their corresponding thermal management needs.

eMobility

In the rapidly expanding field of eMobility, thermal management plays a vital role in ensuring the proper functioning of onboard electronics and processors. In particular, Advanced Driver Assist Systems (ADAS) require effective cooling solutions to maintain optimal performance. By customizing thermal management strategies to address the cooling needs of eMobility applications, companies can enhance the efficiency and reliability of their electric vehicles’ systems.

ADAS Systems

Advanced Driver Assist Systems (ADAS) are at the forefront of the automotive industry’s integration of AI. ADAS systems rely on AI algorithms to analyze sensor data, optimize driving paths, and make real-time decisions. To ensure the accuracy and reliability of these systems, thermal management becomes crucial. Effective cooling solutions tailored for ADAS applications enable the efficient operation of AI hardware, contributing to safer and more sustainable transportation systems.

Medical Devices

Thermal management is of utmost importance in medical devices that incorporate AI technologies. These devices, ranging from diagnostic equipment to wearable health trackers, require precise and consistent operation. A customized thermal management approach helps maintain the optimal temperature of AI hardware within medical devices, ensuring accurate measurements, reliable performance, and patient safety.

By understanding the unique cooling requirements of different AI applications, companies can design and implement effective thermal management solutions. Customized thermal management not only enhances the performance and reliability of AI hardware but also contributes to the advancement and successful integration of AI technologies in various industries.

Key Takeaways:

- Thermal management needs to be tailored to specific AI applications.

- eMobility applications require cooling solutions for onboard electronics and ADAS systems.

- ADAS systems rely on AI algorithms and need effective thermal management for optimal performance.

- Thermal management is critical in medical devices to ensure accurate measurements and patient safety.

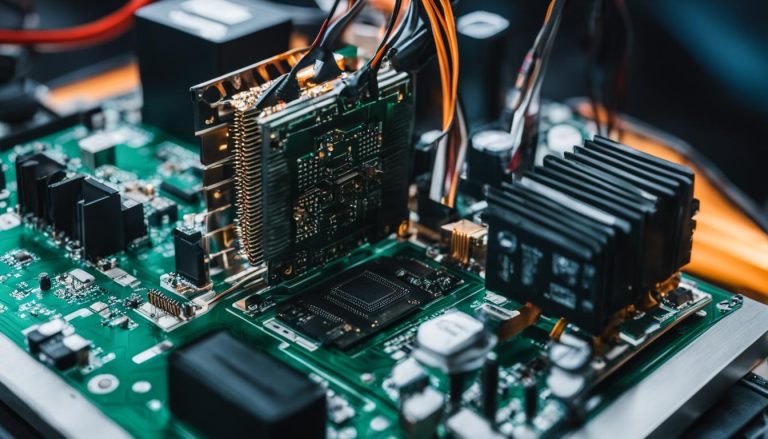

Innovative Thermal Management Solutions

Engineers have developed innovative solutions to address the thermal management challenges associated with AI hardware. These solutions have proven effective in overcoming issues such as excessive heat generation and system failure. Let’s explore some of the key solutions below:

Heat Sinks

Heat sinks are an integral part of thermal management in AI hardware. They effectively absorb and dissipate excess heat, preventing overheating and maintaining optimal operating temperatures. Heat sinks are specifically designed to maximize surface area, allowing for efficient heat transfer and dissipation.

Heat Pipes

Heat pipes are another notable thermal management solution. By leveraging phase change and capillary action, heat pipes efficiently transfer heat from the heat source to the heat sink. These components are particularly well-suited for high-dissipation applications, ensuring effective heat removal.

Thermal Interface Materials (TIMs)

Thermal interface materials (TIMs) play a critical role in enhancing heat transfer between heat sources, such as processors, and heat sinks. TIMs have high thermal conductivity, improving overall thermal performance. These materials fill gaps and imperfections in the interface, minimizing thermal resistance and optimizing heat dissipation.

Liquid Cooling

Liquid cooling systems are gaining popularity in thermal management due to their superior heat removal and dissipation capabilities. These systems utilize liquid coolants to efficiently transfer heat away from AI hardware. Liquid cooling is especially beneficial for mobile AI systems with small form factors and low power consumption.

Air Cooling

Air cooling, the traditional method of heat dissipation, is still widely used in thermal management solutions. By leveraging fans or natural convection, air cooling systems remove heat from AI hardware and maintain optimal temperatures. While not as efficient as liquid cooling, air cooling remains a cost-effective and reliable option.

Both liquid cooling and air cooling play crucial roles in thermal management, with their suitability depending on specific AI hardware requirements and environmental factors.

| Thermal Management Solution | Advantages | Disadvantages |

|---|---|---|

| Heat Sinks | Efficient heat dissipation, cost-effective | Relies on external environment for heat dissipation |

| Heat Pipes | High heat transfer efficiency, suitable for high-dissipation applications | Requires careful design and integration |

| Thermal Interface Materials (TIMs) | Enhances heat transfer, fills gaps and imperfections | Requires proper application for optimal results |

| Liquid Cooling | Superior heat removal capabilities, suitable for compact systems | More complex installation and maintenance |

| Air Cooling | Cost-effective, simple installation | Less efficient than liquid cooling in high-demand scenarios |

These innovative thermal management solutions have revolutionized the field of AI hardware by effectively addressing the challenges posed by excessive heat generation. Engineers continue to explore and develop new strategies to improve thermal performance and ensure the reliability and longevity of AI systems.

Design and Simulation Solutions for Thermal Management

In engineering, designing and optimizing thermal management systems is critical for ensuring the efficient and reliable operation of AI hardware. Engineers utilize various design and simulation techniques to achieve optimal thermal performance in AI hardware.

Computer-Aided Design (CAD) plays a fundamental role in creating and visualizing thermal components. CAD enables engineers to design intricate cooling systems with precision, taking into account factors such as component layout, airflow, and heat dissipation requirements. By leveraging CAD software, engineers can efficiently prototype and refine thermal management solutions while considering the specific constraints and needs of AI hardware.

In addition to CAD, the use of simulation techniques further enhances the design and optimization process for thermal management systems. 3D simulations enable engineers to analyze the heat transfer behavior and temperature distributions within AI hardware, providing valuable insights into the performance characteristics of the cooling solutions.

Through simulations, engineers can simulate various heat transfer scenarios and evaluate the effectiveness of different cooling strategies. These simulations help in identifying potential hotspots, optimizing airflow patterns, and validating the thermal performance of the designed systems.

Integrating CAD and simulations results in an iterative design process that facilitates continuous improvement of thermal performance. By leveraging CAD designs and simulation results, engineers can refine their thermal management solutions, adding innovative features and enhancements. This iterative approach ultimately leads to improved thermal performance and more efficient heat dissipation in AI hardware.

By combining the power of design solutions such as CAD with advanced simulation techniques, engineers can precisely analyze, refine, and optimize the thermal management systems powering AI hardware.

Conclusion

Thermal management plays a critical role in ensuring optimal performance and reliability of AI hardware. As the demand for smaller, more powerful, and energy-efficient computing devices increases, managing excessive waste heat becomes a significant challenge. Customizing thermal management solutions for specific AI applications is essential to meet industry-specific cooling requirements.

Innovative solutions such as heat sinks, heat pipes, thermal interface materials (TIMs), liquid cooling, and air cooling offer efficient cooling for AI hardware. These solutions address the challenges posed by the growing demand for AI technology. Additionally, design and simulation techniques like Computer-Aided Design (CAD) and 3D simulations play a crucial role in optimizing thermal management systems.

Overall, the effective management of thermal issues is vital for the successful implementation and advancement of AI hardware. With customized solutions and advancements in thermal design and simulation techniques, we can continue to overcome the challenges of thermal management and unlock the full potential of AI technology.

FAQ

What is thermal management?

Thermal management refers to the process of controlling and maintaining the temperature of electronic devices to ensure optimal performance and reliability. In the context of AI hardware, thermal management involves managing excessive waste heat generated by AI processors.

Why is thermal management important in AI hardware?

Thermal management is crucial in AI hardware because the increasing demand for smaller, more powerful, and energy-efficient computing devices poses challenges in managing excessive waste heat. Failure to effectively manage the temperature of AI processors can result in performance degradation or system failure.

What are some challenges in thermal management for AI hardware?

One of the challenges in thermal management for AI hardware is the high amount of waste heat generated by specialized processors like graphics processing units (GPUs). Additionally, the demand for smaller form factors and lower power consumption in mobile AI systems requires innovative cooling solutions.

How is thermal management customized for specific AI applications?

Thermal management solutions are customized for specific AI applications based on their cooling requirements. For example, in eMobility applications, thermal management focuses on cooling onboard electronics and processors. Medical devices may have different cooling requirements to maintain optimal performance and reliability.

What are some innovative solutions in thermal management for AI hardware?

Innovative solutions in thermal management for AI hardware include heat sinks, which absorb and dissipate excess heat, heat pipes that efficiently transfer heat using phase change and capillary action, thermal interface materials that improve heat transfer, liquid cooling systems that offer superior heat removal, and air cooling methods.

How are design and simulation techniques used in thermal management?

Design and simulation techniques, such as Computer-Aided Design (CAD) and 3D simulations, are used in thermal management to achieve optimal thermal performance. CAD allows for precise creation and visualization of thermal components, while simulations enable detailed analysis of heat transfer behavior and temperature distributions.

Why is effective thermal management important for AI hardware?

Effective thermal management is important for AI hardware because it ensures optimal performance and reliability. Failure to effectively manage the temperature can result in performance degradation, system failure, and reduced lifespan of AI hardware.