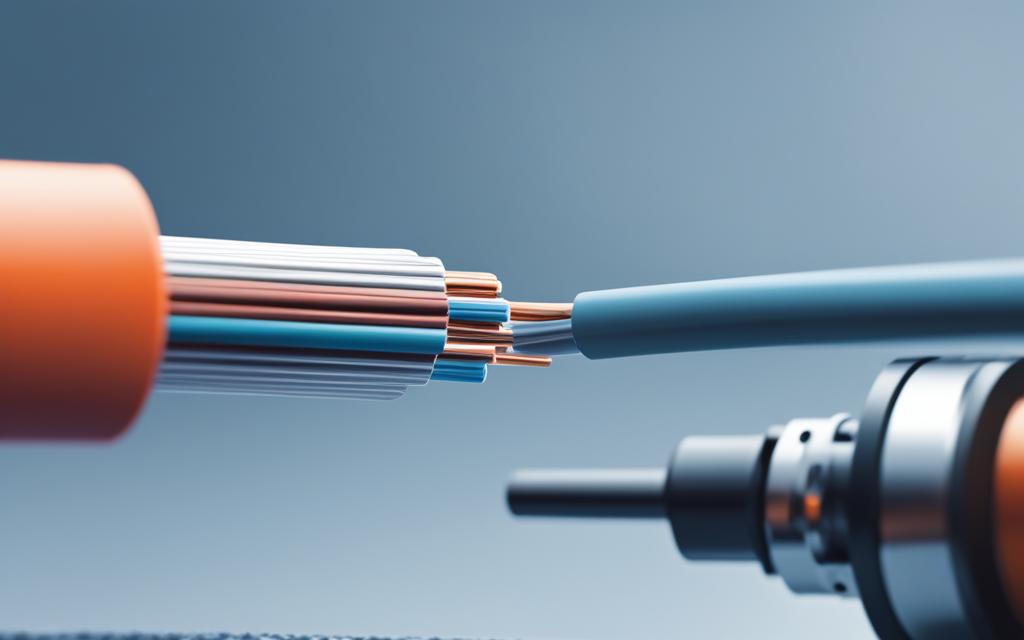

When it comes to specialized network needs, off-the-shelf solutions may not always deliver the desired results. That’s where custom coaxial solutions come into play. By designing tailored solutions, engineers can ensure peak performance and reliability for their network systems.

Custom coaxial solutions are specifically crafted to meet the unique requirements of specialized network applications. Whether it’s in the field of radio, video, audio technology, data systems, telecommunications, or laboratory use, custom coaxial solutions provide the flexibility and precision needed for optimal performance.

In order to design these custom solutions, advanced software tools like CST Studio Suite can be employed to model and optimize coaxial connectors. These solutions are engineered to have a characteristic impedance of 50 Ω or 75 Ω, offering excellent return loss and enabling the transmission of high-frequency signals with minimal interference.

But it’s not just about design. Ensuring the reliability of these connectors is crucial, especially as network demands continue to grow. That’s where thermal simulation comes in. By simulating the thermal behavior of the connectors, engineers can identify potential points of failure and make necessary adjustments to maximize the durability and longevity of the custom coaxial solutions.

Understanding Coaxial Cables: Types and Uses

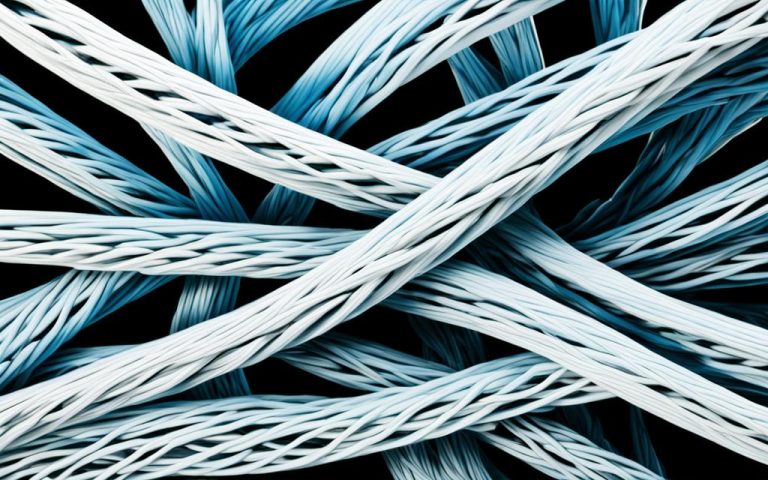

Coaxial cables play a crucial role in transmitting high-frequency or broadband signals for various applications, including television, audio, and data transmission. Understanding the different types and uses of coaxial cables is essential for selecting the right cable for your specific requirements.

There are several types of coaxial cables available in the market, each with its own unique characteristics:

| Type | Description | Impedance |

|---|---|---|

| Hard-line | A rigid coaxial cable used for outdoor applications and high-power transmission. | 75 Ω or 50 Ω |

| Flexible | A versatile and bendable coaxial cable ideal for indoor installations and tight spaces. | 75 Ω or 50 Ω |

| Semi-rigid | Partially flexible coaxial cable commonly used in laboratory setups and test equipment. | 50 Ω |

| Formable | A flexible and shapeable coaxial cable that can be bent and reformed without losing signal integrity. | 50 Ω |

| Rigid | A stiff coaxial cable suitable for applications requiring high mechanical strength and stability. | 75 Ω or 50 Ω |

| Triaxial | A coaxial cable with an additional outer conductor for enhanced signal shielding and reduced interference. | 75 Ω or 50 Ω |

| Twin-axial | A coaxial cable with two center conductors for carrying separate signals or differential signals. | 75 Ω or 50 Ω |

The choice of coaxial cable depends on the specific application’s requirements, such as signal type, distance, and environmental conditions.

Coaxial cables are commonly used for carrying various signals, including:

- Video signals for television broadcasting and video surveillance systems.

- TV antenna signals for high-quality television reception.

- Digital audio signals for audio equipment and sound systems.

It’s important to note that coaxial cables have different impedances, with 75 Ω and 50 Ω being the most common. Matching the impedance of the cable with the equipment and signal source ensures optimal performance and minimal signal loss.

Selecting the Right Cable and Connector

When it comes to selecting coaxial cables for your network, several factors need to be considered to ensure optimal performance. It’s essential to evaluate signal loss, cable construction, and compatibility with connectors. By making informed choices, you can minimize reflections, impedance mismatches, and VSWR, leading to a reliable and efficient transmission line.

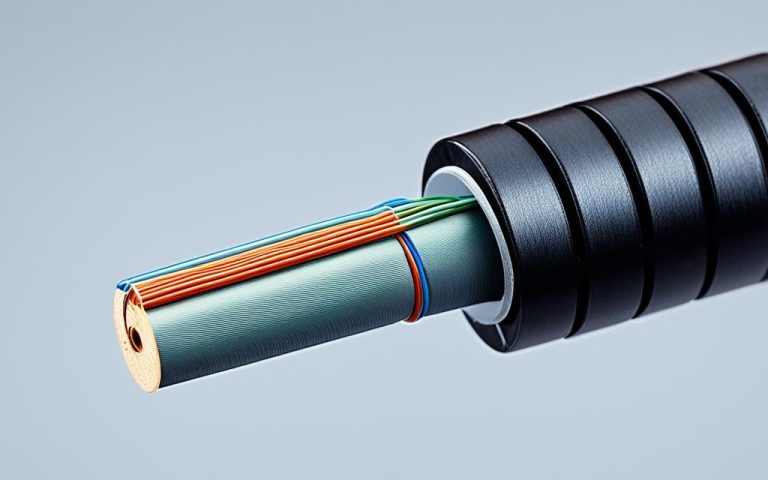

The standard construction of coaxial cables consists of various components that contribute to their overall performance. These include:

- Copper or copper-clad aluminum center conductor: Provides the necessary conducting properties for transmitting signals.

- Closed-cell polyethylene foam dielectric: With its low dielectric constant, it ensures efficient signal transmission and minimizes energy loss.

- Aluminum-mylar-aluminum composite outer conductor tape: Offers excellent shielding properties to protect against interference and minimize signal degradation.

- Round-wire braid: Enhances the overall strength and durability of the cable while improving its shielding capabilities.

In addition to the standard construction, there are other types of coaxial cables designed for specific requirements and applications. These include flexible cables, riser-rated cables, and plenum-rated cables, each suitable for different environmental conditions and installation scenarios.

The choice of connector is equally crucial when it comes to maintaining signal integrity. Connectors play a significant role in the overall performance and reliability of the transmission line. It’s essential to select connectors that are compatible with the chosen cable and offer a secure and reliable connection.

Impedance mismatches within connectors can lead to reflections, resulting in voltage standing wave ratio (VSWR) and signal loss. By choosing connectors that match the impedance of the cable and ensuring proper installation, you can minimize these detrimental effects and maintain a smooth signal transmission.

Proper Termination and Deployment of Coaxial Cables

Proper termination is crucial for the optimal performance of coaxial cables. The termination process involves several essential steps that include cable preparation, soldering, jacket strip-back, and crimping.

To ensure a secure and reliable connection, cable preparation is vital. This involves stripping the cable to the appropriate length and cutting the dielectric and outer conductor square. Proper cable preparation is essential to avoid signal loss and interference.

Soldering the pin and crimping the connector must be done carefully to avoid impedance mismatches and signal reflections. These steps require precision and attention to detail to guarantee optimal signal transmission and minimize signal loss.

The jacket strip-back is another critical step in the termination process. By removing the outer jacket carefully, you can expose the necessary components for a successful termination. This ensures mechanical integrity and maintains electrical performance.

When deploying coaxial cables, it is important to handle and form them properly. Cables should be secured without kinking or bending beyond the minimum bend radius specified by the cable manufacturer. This prevents damage to the cable and maintains optimal signal transmission.

Proper Termination Best Practices:

- Strip the cable to the appropriate length and cut the dielectric and outer conductor square.

- Solder the pin and crimp the connector carefully to avoid impedance mismatches and signal reflections.

- Strip back the jacket properly to ensure mechanical integrity and electrical performance.

- Handle and form the cable without kinking or bending beyond the minimum bend radius.

By following these best practices in cable preparation, termination, and deployment, you can ensure optimal performance and reliability of coaxial cables. Implementing these proper termination techniques minimizes signal loss and helps achieve peak performance in your network.

Conclusion

Optimizing network performance and ensuring reliable data transmission are crucial in today’s fast-paced and interconnected world. The key lies in designing custom coaxial solutions and paying attention to every detail of the network infrastructure.

By carefully selecting the right coaxial cables and connectors, engineers can create tailored solutions that meet the unique needs of specialized networks. Factors such as cable construction, signal loss, and impedance play a vital role in achieving peak performance.

Proper cable preparation, termination, and deployment are equally important in maximizing network performance and reliability. Attention to detail throughout the design and installation process ensures that coaxial cables function optimally, minimizing signal loss and reflections.

In conclusion, by following best practices, utilizing simulation software, and integrating custom coaxial solutions, engineers can optimize network performance and achieve reliable data transmission. The seamless flow of information and reliance on technology demand nothing less than exceptional coaxial solutions for today’s networks.

FAQ

What are coaxial connectors used for?

Coaxial connectors are essential for high-frequency networks such as 5G. They are used in various applications including radio, video, audio technology, laboratory use, data systems, and telecommunications.

What is the characteristic impedance of coaxial connectors?

Coaxial connectors have a characteristic impedance of 50 Ω or 75 Ω and offer excellent return loss. The power that can be transmitted through a coaxial cable depends on the characteristic impedance.

How can software help in designing custom coaxial solutions?

Modeling and optimization using software such as CST Studio Suite can help in designing custom coaxial solutions that meet specific requirements. Thermal simulation is also important to ensure the reliability of the connectors.

What are coaxial cables used for?

Coaxial cables are commonly used for television, audio, and data transmission. They come in different types and are used for carrying video signals, TV antenna signals, and digital audio signals.

What factors should be considered when selecting coaxial cables?

When selecting coaxial cables, factors such as signal loss, cable construction, and compatibility with connectors need to be considered. The choice of coaxial cable depends on the specific requirements of the application.

How should coaxial cables be terminated?

Proper termination of coaxial cables is essential for optimal performance. Cable preparation includes stripping the cable to the appropriate length and cutting the dielectric and outer conductor square. Soldering the pin and crimping the connector must be done carefully to avoid impedance mismatches and signal reflections.

What should be considered during cable deployment?

When deploying coaxial cables, they should be handled, formed, and secured without kinking or bending beyond the minimum bend radius. Paying attention to these details will minimize signal loss and optimize the performance of the cables.

How can engineers optimize network performance with coaxial cables?

Designing custom coaxial solutions and carefully considering cable selection, connector compatibility, cable preparation, termination, and deployment are essential for optimizing network performance and ensuring reliable data transmission.