Coaxial cables play a crucial role in signal transmission for various applications, including video signals, data communication, satellite reception, and aerospace. However, with the multitude of options available, understanding coaxial cable standards and certifications is essential for selecting the right cable for your needs.

There are two main types of coaxial cables: those with an impedance of 75 Ohm (Ω) and those with an impedance of 50 Ohm. Cables with 75 Ohm impedance are primarily used for video signals, while 50 Ohm cables are ideal for data and wireless communications.

It is important to consider standards like CAI (Confederation of Aerial Industries) approval when choosing coaxial cables for digital TV, satellite reception, and CCTV signals. CAI-approved digital coaxial cables undergo rigorous testing to ensure high performance, durability, and safety.

Advancements in coaxial cable technology have also improved signal quality. Solid copper conductors, high-density polyethylene (HDPE) insulation, and dual-shielded designs help to enhance signal transmission, reduce interference, and increase longevity.

For aerospace applications, MIL-DTL-17 coaxial cable standards provide specific requirements for signal cables, including materials, shielding, and impedance. These standards ensure reliable and low-loss signal transmission.

While coaxial cables offer many benefits, they also have limitations. They are not suitable for applications with regular flexing or extreme temperature ranges. Repairs of coaxial cables require careful handling and rejoining of the shield.

By understanding coaxial cable standards, certifications, and technological advancements, you can navigate through the complexity of coaxial cable selection and ensure optimal signal quality for your specific needs.

Understanding CAI Approved Digital Coaxial Cables

When it comes to ensuring high-quality signal transmission for digital TV, satellite reception, and CCTV signals, CAI-approved digital coaxial cables are the go-to choice. CAI stands for the Confederation of Aerial Industries, the leading trade association in the UK’s aerial and satellite industry.

CAI-approved digital coaxial cables have undergone rigorous testing and certification processes to meet strict requirements for performance, durability, and safety. These cables provide reliable and high-quality signal transmission, offering resistance to interference and maintaining longevity.

By choosing CAI-approved digital coaxial cables, you can be confident that your audiovisual system will deliver consistent and crisp digital TV signals, ensuring a flawless viewing experience. Whether you’re enjoying your favorite TV shows, sports events, or movies, these cables provide the necessary signal clarity.

Satellite reception can also benefit greatly from CAI-approved digital coaxial cables. These cables are designed to minimize signal loss, ensuring that your satellite dish receives strong and uninterrupted signals for optimal channel reception. With reliable satellite reception, you can enjoy a wide range of channels, including high-definition content, without any pixelation or signal dropouts.

In addition to digital TV and satellite reception, CAI-approved digital coaxial cables are ideal for transmitting CCTV signals. These cables offer the necessary bandwidth and shielding to ensure clear and stable video transmission, allowing you to monitor your premises with confidence.

Overall, CAI-approved digital coaxial cables provide the essential foundation for a reliable and seamless audiovisual experience. Their adherence to industry standards and focus on performance and durability make them the preferred choice for digital TV, satellite reception, and CCTV signals.

Benefits of CAI Approved Digital Coaxial Cables:

- High-quality signal transmission

- Resistance to interference

- Longevity and durability

- Compliance with industry standards

Applications of CAI Approved Digital Coaxial Cables:

- Digital TV signal transmission

- Satellite reception

- CCTV signal transmission

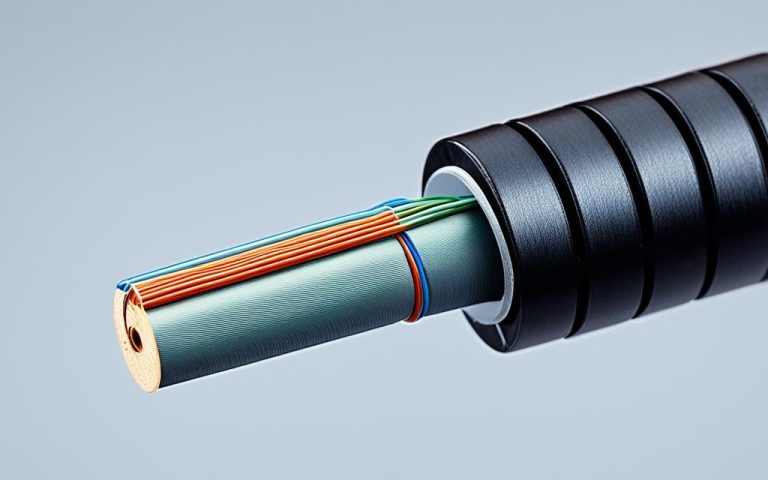

Advancements in Coaxial Cable Technology for Improved Signal Quality

Recent advancements in coaxial cable technology have led to significant improvements in signal quality, enhancing the overall performance of communication systems. These advancements have been achieved through innovative design features and the use of high-quality materials that address common challenges such as signal loss and interference.

Enhanced Transmission with Solid Copper Conductors

One notable improvement is the incorporation of solid copper conductors in coaxial cables. Solid copper, being an excellent conductor, allows for more efficient signal transmission with minimal resistance. This results in better signal integrity and reduces the likelihood of data degradation during transmission.

Impervious to Interference with HDPE Insulation

An essential component of modern coaxial cables is the use of high-density polyethylene (HDPE) insulation. This insulating material offers several key benefits, including resistance to moisture, heat, and chemicals. By preventing the ingress of external elements, HDPE insulation effectively shields the signal from interference, ensuring a reliable and high-quality transmission.

Dual-Shielded Design for Superior Protection

To further enhance signal quality, coaxial cables now feature a dual-shielded design. This design incorporates both foil and braided shielding, providing superior protection against signal loss and interference. The combination of these shielding mechanisms creates an effective barrier, shielding the internal signal from external electromagnetic disturbances that can degrade the signal quality.

An image illustrating the advancements in coaxial cable technology

In summary, the advancements in coaxial cable technology have revolutionized signal transmission by improving signal quality and minimizing disruptions. The incorporation of solid copper conductors ensures efficient and reliable signal transmission, while HDPE insulation provides protection against interference from environmental factors. Additionally, the dual-shielded design offers enhanced shielding capabilities, preserving signal integrity and minimizing signal loss. These advancements make modern coaxial cables an ideal choice for various applications ranging from telecommunications to broadcasting.

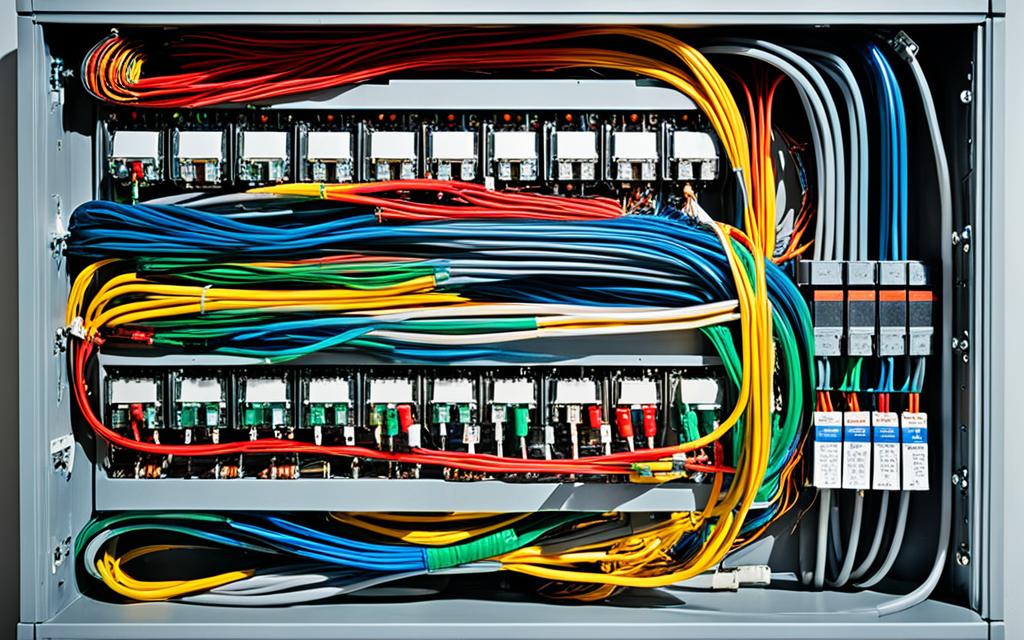

MIL-DTL-17 Coaxial Cable Standards in Aerospace Applications

The MIL-DTL-17 coaxial cable standard plays a vital role in aerospace applications, ensuring reliable signal transmission across a wide range of frequencies. This standard specifies various essential components of coaxial cables, including jacketing materials, shield types, dielectric cores, and conductivity requirements.

Proper shielding is crucial for maintaining optimal system performance in aerospace applications. The MIL-DTL-17 standard addresses this by outlining the necessary shielding specifications, including the use of materials that offer excellent electromagnetic compatibility and protection against interference. Additionally, recent revisions of the standard have introduced requirements for flammability, ensuring the safety of the cables in critical aerospace environments.

Impedance matching is another key aspect considered in the MIL-DTL-17 standard. Maintaining the correct impedance throughout the coaxial cable system is essential for preserving signal strength and minimizing losses. By adhering to the impedance requirements outlined in the standard, aerospace engineers can optimize signal transmission in critical communication systems and ensure efficient operation.

To ensure reliability and performance, coaxial cables designed for aerospace applications must undergo multiple qualification tests. These tests evaluate various parameters, including mechanical durability, electrical performance, and environmental resilience. By subjecting coaxial cables to rigorous testing, the MIL-DTL-17 standard ensures that they meet the stringent requirements of the aerospace industry.

Here’s a brief overview of the MIL-DTL-17 coaxial cable standard:

| Standard Component | Description |

|---|---|

| Jacketing Materials | Specifies the materials used for the external protective layer of the coaxial cable, taking into account factors such as environmental resistance and chemical compatibility. |

| Shield Types | Defines the type of shielding used to protect the coaxial cable from electromagnetic interference, ensuring optimal signal quality and reliability. |

| Dielectric Cores | Specifies the dielectric material used within the coaxial cable, ensuring low-loss characteristics and maintaining the desired impedance. |

| Conductivity Requirements | Sets the standards for the electrical conductivity of the coaxial cable’s core and conductive elements, ensuring efficient signal transmission. |

The MIL-DTL-17 coaxial cable standard provides a comprehensive framework for the design and implementation of coaxial cables in aerospace applications. By adhering to these standards, engineers can ensure reliable signal transmission and meet the demanding requirements of the aerospace industry.

Benefits and Limitations of Coaxial Cables in EWIS Design

Coaxial cables play a critical role in Electrical Wiring Interconnection System (EWIS) design, ensuring reliable signal transmission and maintaining signal quality. However, it is important to be aware of both the benefits and limitations of coaxial cables in this application.

Benefits of Coaxial Cables in EWIS Design

- Reliable Signal Transmission: Coaxial cables are designed to minimize signal loss and interference, making them ideal for carrying electrical signals over long distances without degradation.

- Diverse Options: Coaxial cables offer a wide range of options for jacketing materials, shielding, and dielectric cores, allowing flexibility in design and customization based on specific project requirements.

Limitations of Coaxial Cables in EWIS Design

Not Ideal for Flexing Applications: Coaxial cables are not suitable for applications that involve frequent flexing or bending, as this can lead to damage and signal degradation.

Temperature Range Limitations: Coaxial cables have limited temperature ranges, making them unsuitable for use in environments near engines or other high-temperature sources.

Complex Repairs: Repairs on coaxial cables require careful handling and rejoining of the shield and dielectric, which can be a complex and time-consuming process.

Despite these limitations, coaxial cables remain a popular choice for EWIS design due to their reliable signal transmission capabilities and the ability to customize them to meet specific project needs.

Maintaining Optimal Signal Quality with Coaxial Cables

Maintaining optimal signal quality with coaxial cables is crucial for ensuring reliable and high-performance signal transmission. To achieve this, several factors need to be considered, including impedance matching and verification tests.

Impedance Matching

Impedance matching plays a vital role in minimizing signal loss and reflections along the coaxial cable. It involves ensuring that the impedance of mating connections, such as connectors and devices, is correctly matched to the cable’s impedance. By maintaining the right impedance levels, the risk of signal degradation and distortion can be significantly reduced, leading to improved overall signal quality.

Verification Tests

To ensure the reliability and performance of coaxial cables, rigorous verification tests are conducted. These tests evaluate various parameters that directly impact the cable’s signal transmission capabilities.

Velocity of Propagation: This test measures the speed at which electrical signals travel through the cable. A consistent velocity of propagation is essential for maintaining signal integrity and reducing latency.

DC Resistance: Measuring the direct current (DC) resistance of a coaxial cable helps identify potential power losses and signal attenuation. Lower DC resistance values indicate better signal conductivity and reduced power losses.

Aging Stability: Coaxial cables are subjected to aging stability tests to assess their long-term performance and durability. These tests simulate the effects of environmental factors such as temperature and moisture, ensuring that the cable can withstand challenging conditions without significant signal degradation.

Tear Strength: The tear strength test evaluates the cable’s resistance to physical damage or tearing. Cables with higher tear strength are more durable and less prone to signal loss caused by external factors like cable handling or installation.

Advanced technologies such as Time Domain Reflectometry (TDR) can also be utilized to identify circuit interrupts and impedance changes within the coaxial cable. These diagnostic tools provide valuable insights into the cable’s performance and facilitate prompt troubleshooting and maintenance.

By prioritizing impedance matching and conducting rigorous verification tests, organizations can ensure the optimal signal quality of their coaxial cable installations. This, in turn, leads to reliable data transmission, improved system performance, and enhanced user experiences.

Conclusion

Coaxial cables are a reliable and cost-effective solution for signal transmission in various applications. Whether it’s for video signals, data communication, satellite reception, or even aerospace, coaxial cables have proven their versatility time and again. Understanding the different standards and certifications, as well as the advancements in technology, is crucial for selecting the right coaxial cable and ensuring optimal signal quality.

Coaxial cables offer numerous benefits, such as high-quality signal transmission, resistance to interference, and longevity. With advancements in technology, newer cables feature solid copper conductors for improved efficiency, HDPE insulation for better protection against signal loss, and a dual-shielded design for superior shielding performance.

While coaxial cables have their limitations, such as limited temperature ranges and challenges with repairs, they remain a reliable and widely used option. By maintaining proper impedance matching and conducting verification tests, the signal quality of coaxial cables can be optimized for maximum performance.

FAQ

What are the two main types of coaxial cables?

The two main types of coaxial cables are those with an impedance of 75 Ohm (Ω) and those with an impedance of 50 Ohm.

What are 75 Ohm coaxial cables primarily used for?

75 Ohm coaxial cables are mostly used for video signals.

What are 50 Ohm coaxial cables typically used for?

50 Ohm coaxial cables tend to be used for data and wireless communications.

What is the role of RF coaxial cables in TVs?

RF coaxial cables serve as the standard input cable for TVs, carrying radio frequency signals.

What is the difference between RG-6 and RG-59 coaxial cables?

RG-6 cables provide better signal quality and are designed to handle GHz level signals effectively. RG-59 cables are thinner and are suitable for short runs and low-frequency transmissions.

How do RG-11 coaxial cables differ from other types?

RG-11 cables are thicker and offer lower attenuation levels, making them suitable for longer distance data transmission.

What does CAI stand for?

CAI stands for the Confederation of Aerial Industries, the UK’s leading trade association for the aerial and satellite industry.

What are CAI-approved digital coaxial cables?

CAI-approved digital coaxial cables have been thoroughly tested and certified to meet strict requirements for performance, durability, and safety. They ensure high-quality signal transmission, resistance to interference, longevity, and compliance with industry standards for digital TV, satellite reception, and CCTV signals.

How have recent advancements improved coaxial cable technology?

Recent advancements in coaxial cable technology include the use of solid copper conductors, which are more efficient at transmitting signals and have low resistance. High-density polyethylene (HDPE) insulation provides resistance to moisture, heat, and chemicals, preventing signal loss and interference. Coaxial cables now feature a dual-shielded design with both foil and braided shielding for superior protection against signal loss and interference.

What does the MIL-DTL-17 coaxial cable standard cover?

The MIL-DTL-17 coaxial cable standard covers signal cables designed for low-loss, stable operation from low to high frequencies. It specifies materials such as jacketing materials, shield types, dielectric cores, and conductivity requirements. Proper shielding is crucial for good system performance, and flammability has become a requirement in recent iterations of the standard.

What are the benefits and limitations of coaxial cables in EWIS design?

Coaxial cables are reliable and provide reliable signal transmission. They have various options for jacketing materials, shielding, and dielectric cores. However, they are not ideal for regular flexing applications and have limited temperature ranges, making them unsuitable for use near engines. Repairs require careful handling of the dielectric and rejoining of the shield.

How can one maintain optimal signal quality with coaxial cables?

Maintaining optimal signal quality with coaxial cables requires proper impedance matching, ensuring the impedance of mating connections is correct to prevent signal loss or reflection. Verification tests such as velocity of propagation, DC resistance, aging stability, and tear strength are performed to ensure cable reliability. Time Domain Reflectometry (TDR) technologies can be used to identify circuit interrupts and impedance changes.