Welcome to our comprehensive guide on repairing coaxial cables. Whether you’re facing a temporary cable repair issue or need a waterproof solution, we’ve got you covered.

Introducing the Cable Repair Kit – the perfect solution for temporarily repairing damaged coaxial cables. This versatile kit includes two essential materials: Coax Seal and Silicone Tape. The Coax Seal, a hand moldable plastic, creates a watertight barrier, while the flexible Silicone Tape provides protection from debris.

Designed to meet the needs of divers and individuals requiring a quick fix, the Cable Repair Kit is a convenient temporary solution. It allows you to maintain connection quality while you arrange for a permanent replacement. However, it is important to note that damaged cables should be replaced as soon as possible for optimal performance.

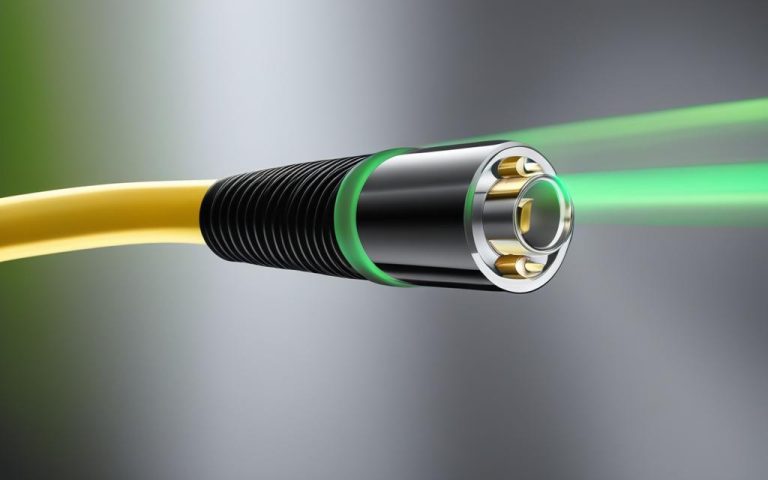

Understanding Coaxial Cables and their Construction

Coaxial cables play a crucial role in the electrical transmission of high radio frequency (RF) signals. These cables consist of four main components, each serving a specific purpose in maintaining signal integrity.

- Center Conductor: The center conductor is the core component of a coaxial cable. It is responsible for carrying the RF signals from the source to the destination. Typically made of copper or aluminum, the center conductor provides low resistance and minimizes signal loss.

- Dielectric Insulator: Surrounding the center conductor is the dielectric insulator. This insulating material maintains the precise distance between the conductor and the shield. By keeping the two components separate, the dielectric insulator ensures optimal signal transmission and reduces the risk of interference.

- Braided Shield: The braided shield serves as a critical component for minimizing external interference. Composed of woven copper or aluminum, the shield cancels out unwanted electromagnetic signals, preventing them from corrupting the RF signals within the cable.

- Jacket: The outermost layer of a coaxial cable is the jacket. It provides physical protection to the internal components and safeguards against environmental factors such as moisture and abrasion. The jacket material is typically a non-conductive polymer, ensuring insulation and durability.

These four components work in harmony to ensure the efficient and reliable transmission of RF signals. The construction of coaxial cables is optimized for various applications, including cable TV, internet connections, and cell boosters.

Speaking of applications, let’s take a closer look at the different uses and types of coaxial cables in the next section.

Common Uses and Types of Coaxial Cables

Coaxial cables are versatile and widely used in various applications, providing reliable signal transmission and communication. Let’s explore some common uses and types of coaxial cables:

Cable TV

Coaxial cables are crucial for delivering cable TV signals to your television. They connect the cable company’s signal source to your TV, ensuring high-quality video and audio transmission.

Signal Boosters

Coaxial cables are also integral to signal boosters, which enhance cellular signals for improved call quality and data speeds. These boosters use coaxial cables to connect antennas to mobile devices, amplifying signal strength and extending coverage.

Cable Internet

Coaxial cables play a significant role in cable internet connections, delivering high-speed internet access to homes and businesses. These cables provide reliable and fast data transmission, allowing for seamless browsing, streaming, and online activities.

Ham Radio

Amateur radio operators, or “hams,” rely on coaxial cables for long-range communication. Coaxial cables facilitate the transmission of radio signals, allowing hams to communicate with other operators around the world. These cables ensure efficient signal transmission and minimize interference.

Types of Coaxial Cables

There are different types of coaxial cables available, each designed for specific purposes and requirements. Some notable types include:

| Type | Applications |

|---|---|

| RG coax cables |

|

| LMR coax cables |

|

RG coax cables, such as RG-6 and RG-11, are commonly used in cable TV and satellite TV installations. They offer excellent signal quality and are suitable for high-frequency applications. On the other hand, LMR coax cables, such as LMR-200 and LMR-400, find applications in wireless communications, public safety radio, and cellular networks. These cables are known for their durability, low loss, and flexibility.

By understanding the common uses and types of coaxial cables, you can make informed decisions when selecting the right cable for your specific needs. Whether it’s for cable TV, signal boosters, cable internet, or ham radio, choosing the appropriate coaxial cable ensures reliable and efficient signal transmission.

Understanding Coaxial Cable Connectors

Coaxial cable connectors play a crucial role in ensuring a secure and reliable connection between coaxial cables. They come in three main types: male connectors, female connectors, and genderless connectors.

Male connectors feature a pin or protrusion that fits into slots or indentations in female connectors. This design allows for a secure and stable connection, preventing any accidental disconnections.

Female connectors have a tube that contains the male pin and an outer cylinder that functions as an electrical contact point. By combining these two components, female connectors provide a receptacle for male connectors to be inserted into, creating a solid connection.

Genderless connectors, also known as combination connectors, are designed to be versatile and flexible. They can be connected to both male and female connectors of matching size and type. This feature eliminates the need for specific gender connectors and simplifies installation and maintenance processes.

When selecting a coaxial cable connector, it’s important to consider the voltage, environmental conditions, and required frequency. Choosing the appropriate connector ensures optimal performance and minimizes signal loss or interference.

The Importance of Coaxial Cable Connectors

Coaxial cable connectors are the critical components that establish and maintain the electrical connection between cables. They contribute to overall signal quality and reliability. Without properly functioning connectors, coaxial cables can experience signal degradation, leading to poor picture quality, slow internet speeds, or interrupted communication.

“The quality and compatibility of the connectors used significantly impact the performance and longevity of coaxial cable connections.”

To further understand the significance of coaxial cable connectors, consider the following points:

- Connectivity: The connectors enable the connection of coaxial cables to devices such as televisions, modems, antennas, and signal boosters.

- Signal Integrity: Properly installed connectors ensure a strong and continuous signal flow, promoting clear communication and high-quality transmission.

- Ease of Installation: Coaxial cable connectors are designed for easy installation and removal, enabling efficient cable management and maintenance.

- Durability: Well-constructed connectors with quality materials ensure long-lasting performance, even in demanding environments.

By understanding the different types and functionalities of coaxial cable connectors, users can make informed decisions when selecting and installing these components.

Coaxial Cable Connector Types

In addition to the main types of coaxial cable connectors, there are various specific connector models available in the market. These models have different designs and specifications tailored to meet specific needs and requirements. Some examples of popular coaxial cable connector types include:

| Connector Type | Description | Common Applications |

|---|---|---|

| BNC (Bayonet Neill-Concelman) | A quick-connect/disconnect connector with a bayonet-style mechanism. | CCTV systems, radio equipment, test equipment |

| F-Type | A screw-on connector commonly used in television and broadband applications. | Cable TV, satellite TV, modems |

| N-Type | A threaded connector known for its high power handling capabilities and durability. | Wireless systems, industrial applications |

| SMA (SubMiniature version A) | A compact, threaded connector used in high-frequency applications. | Cellular antennas, Wi-Fi routers, GPS devices |

These are just a few examples of the many coaxial cable connector types available. Each connector type has its own advantages and is suitable for specific applications based on factors such as frequency range, power handling capacity, and compatibility.

Understanding and selecting the appropriate coaxial cable connectors for a particular use case is essential to ensure optimal performance and signal integrity.

Tips for Coaxial Cable Repair and Maintenance

When it comes to repairing coaxial cables, proper preparation is crucial. Before starting the repair process, ensure that the cable is free from debris and moisture. Cleaning the affected area will help ensure a successful repair and maintain the connection quality.

To repair the damaged area, you can use a Coax Seal, which is a hand moldable plastic designed to create a watertight barrier. Cut a piece of Coax Seal and mold it onto the damaged area, overlapping each winding by 50%. This will provide a secure and reliable temporary repair solution.

After applying the Coax Seal, it’s recommended to wrap the repaired area with silicone tape. Silicone tape is a flexible tape that provides additional protection from moisture and debris. Similar to the Coax Seal, ensure that each winding of the tape overlaps for maximum effectiveness.

Regular maintenance and inspection of coaxial cables are essential to prevent further damage and identify any potential issues. By regularly checking the cables, you can catch any signs of wear or damage early on, allowing for prompt repairs or replacements.

Remember, while temporary repairs can help maintain connection quality, it’s important to replace damaged cables as soon as possible to ensure a reliable and long-term solution.

Following these cable repair tips, including proper cable preparation, surface cleaning, coax seal application, and silicone tape wrapping, can help you effectively repair and maintain coaxial cables, ensuring optimal performance and durability.

Conclusion

The use of the Cable Repair Kit can be a valuable solution for temporarily restoring connection quality in damaged coaxial cables. By following proper cable repair best practices, including cable preparation, applying the Coax Seal, and wrapping the silicone tape, you can effectively restore the functionality of your cables. However, it’s important to note that this repair is not a permanent fix.

While the temporary repair can help maintain connection quality in the short term, it’s advisable to replace damaged cables as soon as possible. Regular maintenance and inspection of your coaxial cables are essential to identify any potential issues and prevent further damage.

By adhering to the coaxial cable repair guide provided and implementing effective restoration techniques, you can ensure that your cable connections remain reliable and deliver optimal performance. Investing the time and effort into proper cable repair and maintenance will help you avoid potential disruptions and optimize your overall connectivity experience.

FAQ

What is the Cable Repair Kit?

The Cable Repair Kit is a handy solution for temporarily repairing damaged coaxial cables. It includes two specialized materials: Coax Seal and Silicone Tape. The Coax Seal is a hand moldable plastic that creates a watertight barrier, while the Silicone Tape is a flexible tape that protects from debris. This field repair kit is perfect for divers or anyone needing a quick fix for a damaged cable.

Are the repairs made with the Cable Repair Kit permanent?

No, the repairs made with the Cable Repair Kit are not permanent solutions. Damaged cables should be replaced as soon as possible. The kit provides a temporary fix to maintain connection quality until a permanent replacement can be made.

What are coaxial cables used for?

Coaxial cables are commonly used for electrical transmission of high radio frequency (RF) signals. They are essential for cable TV, connecting the cable company’s signal to your TV. Coaxial cables are also used in signal boosters to enhance cellular signal, cable internet for high-speed internet access, and ham radio for long-range communication.

What types of coaxial cables are available?

There are different types of coaxial cables available, including RG coax cables (such as RG-6 and RG-11) and LMR coax cables (such as LMR-200 and LMR-400). Each type of cable is designed for specific uses and has different characteristics.

What are the main types of coaxial cable connectors?

The main types of coaxial cable connectors are male connectors, female connectors, and genderless connectors. Male connectors have a pin or protrusion that fits into slots or indentations in female connectors. Female connectors have a tube that contains the male pin and an outer cylinder that functions as an electrical contact point. Genderless connectors, also known as combination connectors, can be connected to both male and female connectors of matching size and type.

How do I repair a coaxial cable using the Cable Repair Kit?

To repair a coaxial cable using the Cable Repair Kit, start by cleaning the affected area and ensuring it is free of debris and moisture. Then, apply the Coax Seal to the damaged area by cutting a piece and molding it onto the cable, overlapping each winding by 50%. Finally, wrap the silicone tape around the cable, overlapping each winding. This temporary repair solution can help maintain connection quality until a permanent replacement can be made.

Is regular maintenance and inspection of coaxial cables necessary?

Yes, regular maintenance and inspection of coaxial cables are recommended. This helps identify any potential issues and prevent further damage. It is important to check for any signs of wear or damage and address them promptly to ensure optimal performance of the cables.