Twisted pair cables are a critical component of network infrastructure, and their performance and safety are determined by certification standards. These standards ensure that the cables meet the necessary requirements for protection, performance, administration, and compatibility. The ANSI/TIA 568 C.2 standard, developed by the Telecommunications Industry Association (TIA), is a comprehensive guide that covers twisted pair cabling and components in categories such as Category 3, Category 5e, Category 6, and Category 6A.

The ANSI/TIA 568 C.2 standard is divided into three main sections: General, Mechanical Requirements, and Transmission Requirements. It specifies mandatory and advisory criteria for each category of cable, ensuring that manufacturers and purchasers have a common understanding.

It is important to note that the standard does not recognize older legacy cabling standards such as Category 1, 2, 4, and 5. Compliance with these certification standards is essential for manufacturers, purchasers, and datacom contractors to guarantee the quality and reliability of network installations.

In this article, we will explore the various sections of the ANSI/TIA 568 C.2 standard in detail, starting with the General Requirements, followed by the Mechanical Requirements and Transmission Requirements. We will also discuss the importance of adhering to these certification standards, as well as the role of certification testers in verifying compliance.

General Requirements of Twisted Pair Cables Certification Standards

The general section of the ANSI/TIA 568 C.2 standard outlines the important requirements and guidelines for twisted pair cables. These standards ensure the backward compatibility and interoperability of different cable versions, allowing newer cables to function with older ones. However, the performance of the system will be limited by the slowest component.

The ANSI/TIA 568 C.2 standard also defines the recognized cable categories, including Category 3, Category 5e, Category 6, and Category 6A, along with their specific transmission characteristics. For instance, Category 3 cables have a transmission characteristic of 1 to 16 MHz, while Category 6A cables can transmit signals within the range of 1 to 500 MHz.

Furthermore, the general section of the standard provides standardized pinouts, T568A and T568B, for eight-position modular connectors. These pinouts ensure consistency and compatibility in wiring schemes, facilitating proper connections and installations.

Implementing the general requirements laid out in the ANSI/TIA 568 C.2 standard is crucial for ensuring the reliability, performance, and compatibility of twisted pair cable installations.

Mechanical Requirements of Twisted Pair Cables Certification Standards

The Mechanical Requirements section of the ANSI/TIA 568 C.2 standard focuses on the physical characteristics and mechanical performance specifications that twisted pair cables must meet. These requirements ensure that the cables are constructed to the necessary standards to guarantee their reliability and functionality.

According to the standard, twisted pair cables should have four twisted pairs with solid or stranded conductors sized between 22AWG and 24AWG. This ensures that the conductors can effectively carry signals and transmit data without interference. The cables should also have thermoplastic insulation, which provides protection against external factors that could potentially damage the conductors.

Additionally, the standard states that twisted pair cables must have an overall thermoplastic jacket with a diameter less than or equal to 9.0mm. This jacket offers further protection to the internal components of the cable and enhances its durability. It also ensures compatibility with various networking equipment and connectors.

The internal color code of the conductors is another essential aspect addressed by the Mechanical Requirements section. This color code is important for proper installation and termination as it allows technicians to identify and connect the appropriate conductors accurately.

Furthermore, the Mechanical Requirements section outlines the testing and test methods that the cables must undergo to ensure they meet the mechanical performance requirements. These tests assess various factors such as tensile strength, bending radius, and flame retardancy to determine the cables’ suitability for installation in different environments and applications.

Overall, adherence to the Mechanical Requirements specified in the certification standards for twisted pair cables is crucial to ensure the cables’ physical integrity, compatibility, and performance in various networking scenarios.

| Physical Characteristics | Requirements |

|---|---|

| Conductors | Four twisted pairs with solid or stranded conductors sized between 22AWG and 24AWG |

| Insulation | Thermoplastic insulation |

| Jacket | Overall thermoplastic jacket with a diameter less than or equal to 9.0mm |

| Color Code | Internal color code for proper installation and termination |

Transmission Requirements of Twisted Pair Cables Certification Standards

The Transmission Requirements section of the ANSI/TIA 568 C.2 standard focuses on the performance specifications of twisted pair cables and components. These requirements are vital to ensure optimal signal quality and data integrity in network installations.

The standard outlines various parameters that are crucial for determining the performance of the cables, including:

- Return Loss

- Insertion Loss

- Near End Crosstalk Loss (NEXT)

- Far End Crosstalk Loss (FEXT)

- Attenuation Crosstalk Ratio Far End (ACRF)

- Transverse Conversion Loss (TCL)

- Propagation Delay

Each of these parameters plays a significant role in maintaining the integrity of the transmitted signals, ensuring that they don’t degrade or interfere with other signals.

The standard provides acceptable limits for each parameter, allowing manufacturers and purchasers to evaluate and compare the performance of twisted pair cables effectively. These limits act as benchmarks to assess whether the cables meet the required performance standards.

To measure and validate the compliance of twisted pair cables with the transmission requirements, the standard also specifies the testing methods that should be employed. Following these testing procedures ensures accurate and reliable results.

Ensuring that twisted pair cables meet the transmission requirements is critical for establishing a robust and reliable network infrastructure. Compliance with these standards guarantees the proper functioning of the network, preventing signal degradation, data loss, and disruptions in communication.

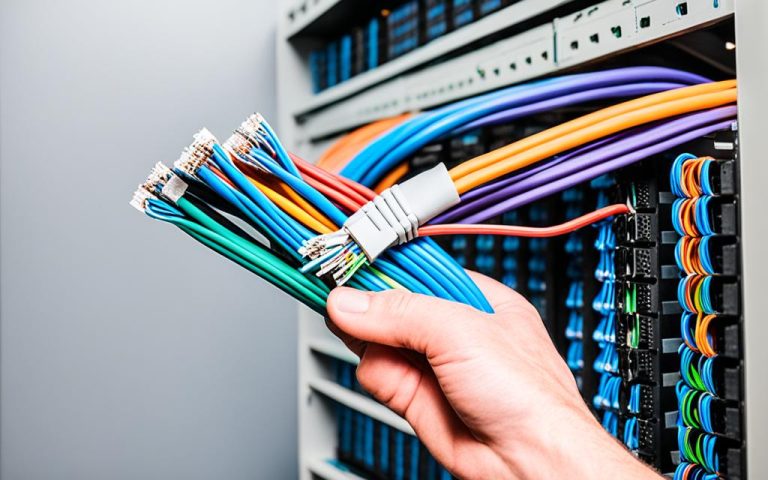

Cabling Standards and Certification Testers

In addition to the standards for twisted pair cables, there are also cabling standards set by bodies such as TIA or ISO/IEC. These standards consider factors like current and future networking technologies, cable construction technologies, installation practices, and operating environments. They specify the requirements for components, cabling channels, and links.

Certification testers play a crucial role in verifying compliance with these standards. They are used to perform a series of tests to certify that the installation meets the specified performance criteria. The tests include:

- wiremap

- propagation delay

- delay skew

- cable length

- insertion loss

- return loss

- near-end crosstalk

- power sum near-end crosstalk

- equal-level far-end crosstalk

- power sum equal-level far-end crosstalk

- attenuation-to-crosstalk ratio

- power sum attenuation-to-crosstalk ratio

- DC loop resistance

These certification testers ensure that the installation meets the necessary performance requirements, ensuring network reliability and data integrity.

Key Takeaways:

- Cabling standards set requirements for components, cabling channels, and links.

- Certification testers are used to verify compliance with these standards.

- Certification tests ensure the installation meets the specified performance criteria.

- The tests cover various parameters like wiremap, delay, crosstalk, and resistance.

- Certification testers play a crucial role in ensuring network reliability and data integrity.

Conclusion

Twisted pair cables certification standards are vital for ensuring the performance and safety of network infrastructure. The ANSI/TIA 568 C.2 standard serves as a comprehensive guide, providing the necessary requirements and criteria for each category of cable. Compliance with these standards is essential for manufacturers, purchasers, and datacom contractors to guarantee the quality and reliability of network installations.

Certification testers play a crucial role in verifying compliance with cabling standards. These testers allow installers to warranty their work and provide network owners with the confidence that the infrastructure can support specific applications. By adhering to these certification standards, organizations can ensure optimal network performance and minimize the risk of downtime or data loss.

Ensuring that twisted pair cables meet the relevant certification standards is not only a best practice but also a necessity for building a reliable and efficient network. By following the ANSI/TIA 568 C.2 standard and utilizing certification testers, organizations can establish a solid foundation for their network infrastructure.

FAQ

What are twisted pair cables certification standards?

Twisted pair cables certification standards are comprehensive guidelines that determine the performance and safety requirements for twisted pair cabling and its components.

What is the ANSI/TIA 568 C.2 standard?

The ANSI/TIA 568 C.2 standard, developed by the Telecommunications Industry Association (TIA), is a comprehensive guide that covers twisted-pair cabling and components in categories such as Category 3, Category 5e, Category 6, and Category 6A.

What does the ANSI/TIA 568 C.2 standard cover?

The ANSI/TIA 568 C.2 standard covers twisted-pair cabling and components, specifying requirements for protection, performance, administration, and compatibility. It is divided into three main sections: General, Mechanical Requirements, and Transmission Requirements.

What are the transmission characteristics of different cable categories?

The transmission characteristics vary for different cable categories. For example, Category 3 cables have a transmission characteristic of 1 to 16 MHz, while Category 6A cables have a characteristic of 1 to 500 MHz.

What are the mechanical requirements for twisted pair cables?

The mechanical requirements include specifications for cable construction, such as having four twisted pairs with solid or stranded conductors sized between 22AWG and 24AWG, thermoplastic insulation, and an overall thermoplastic jacket with a diameter less than or equal to 9.0mm.

What are the parameters covered in the transmission requirements section?

The transmission requirements section covers parameters such as return loss, insertion loss, near end crosstalk loss (NEXT), far end crosstalk loss (FEXT), attenuation crosstalk ratio far end (ACRF), transverse conversion loss (TCL), and propagation delay.

What are cabling standards and what is their importance?

Cabling standards are set by bodies such as TIA or ISO/IEC and specify requirements for components, cabling channels, and links. They consider factors like networking technologies, cable construction, installation practices, and operating environments. Compliance with these standards ensures optimal network performance and reliability.

How do certification testers verify compliance with cabling standards?

Certification testers are used to perform a series of tests, including wiremap, propagation delay, delay skew, cable length, insertion loss, return loss, near-end crosstalk, power sum near-end crosstalk, equal-level far-end crosstalk, power sum equal-level far-end crosstalk, attenuation-to-crosstalk ratio, power sum attenuation-to-crosstalk ratio, and DC loop resistance.

Why are twisted pair cables certification standards important?

Twisted pair cables certification standards ensure the performance and safety of network infrastructure. Compliance with these standards is essential for manufacturers, purchasers, and datacom contractors to guarantee the quality and reliability of network installations.