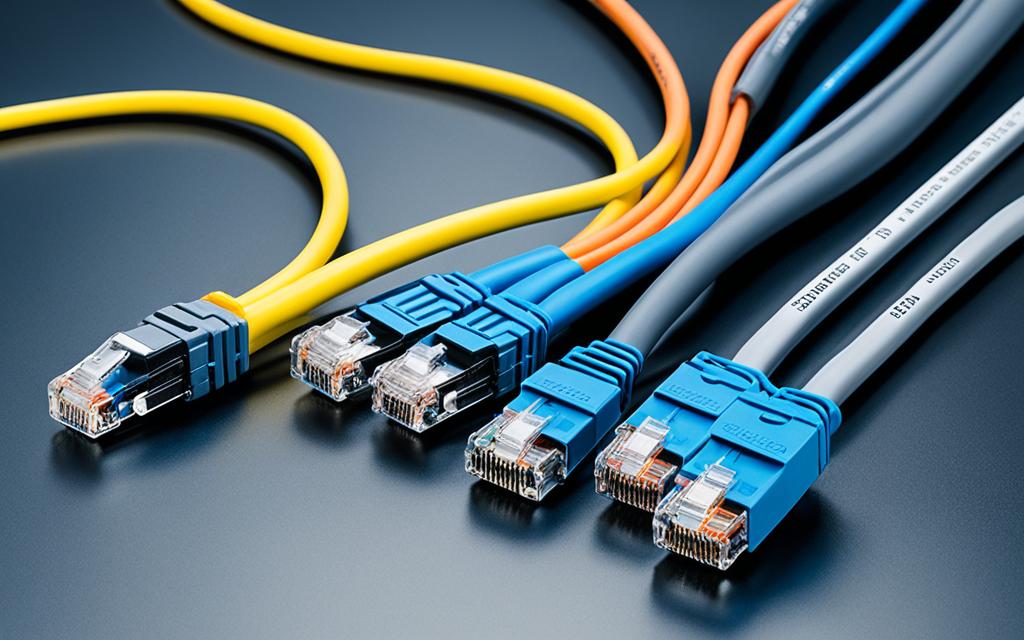

Patch cord cables, also known as Ethernet cables, are crucial for maintaining reliable connectivity and optimizing network performance. Choosing the right patch cables can ensure smooth data transmission and efficient communication within your network.

When it comes to patch cable selection, there are several factors to consider. The first step is to understand the different cable categories available, such as Cat 5e, Cat 6, Cat 6a, and Cat 7. Each category offers varying levels of performance and data transmission capabilities.

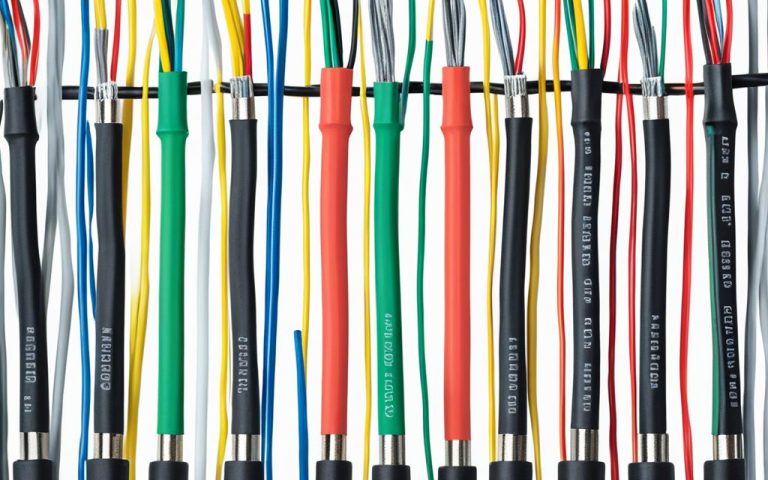

Once you have determined the appropriate category for your network, it is important to consider the specific needs of your setup. Customization options, such as cable length and color-coded connectors, can enhance cable management and ease of identification.

In addition to customization, it is essential to choose patch cables from reliable manufacturers that adhere to industry standards and conduct rigorous testing procedures. A reputable brand like ACT can provide high-quality cables that meet your network’s requirements.

By taking these factors into account and selecting the right patch cables, you can ensure reliable connectivity and optimal network performance for your organization.

Factors to Consider When Choosing a Patch Cord Cable Manufacturer

When selecting a patch cord cable manufacturer, it is crucial to consider several factors. First and foremost, prioritize the quality and performance of the manufacturer’s products. Look for manufacturers that adhere to industry standards, offer certified cables, and conduct rigorous testing procedures to ensure reliable and high-performing patch cord cables.

Additionally, consider the cable category and specifications that best suit your networking needs. Whether you require Cat 5e, Cat 6, Cat 6a, or Cat 7 cables, make sure the manufacturer offers the specific cable category and customization options for cable lengths. This flexibility provides efficient cable management and ensures that your network functions optimally.

Reliability and durability are paramount when it comes to patch cord cables. Therefore, choose manufacturers that use high-quality materials and offer warranties or guarantees. This commitment to quality and durability ensures that your patch cord cables will withstand the demands of your network and provide consistent performance.

Finally, thoroughly research the manufacturer’s reputation and track record. By doing so, you can confirm their reliability, customer satisfaction, and reliable support. Opt for manufacturers with a strong reputation in the industry to minimize the risk of any issues and ensure a smooth experience.

By carefully considering the factors mentioned above – quality and performance, cable category and customization, reliability and durability, and reputation – you can make an informed decision when selecting a patch cord cable manufacturer. This meticulous approach will enable you to receive high-quality patch cord cables that meet your network’s requirements and provide seamless connectivity.

Different Types of Patch Cables for Specific Applications

Patch cables are available in various types, each designed to meet specific application requirements. Understanding the different types of patch cables can help you choose the most suitable option for your network.

Duplex Patch Cables

Duplex patch cables are commonly used for two-way communication, allowing data transmission via two fibers. They are ideal for applications where simultaneous data transmission and reception are required.

Polarity Twist Cables

Polarity Twist™ cables offer a space-saving solution for quick polarity changes. These cables allow for efficient cable management while ensuring reliable connectivity. They are a suitable choice for environments with limited space.

Short Boot Patch Cables

Short boot patch cables are specifically designed for use in limited space environments. They have shorter connector boots, which minimize the space required for cable connections. These cables provide flexibility and efficient cable management in tight spaces.

Ruggedized Patch Cables

Ruggedized patch cables are built to withstand harsh environments and provide better mechanical protection for longer cable lengths. They are equipped with durable materials and enhanced strain relief features, making them ideal for industrial settings or outdoor installations.

Armoured Patch Cables

Armoured patch cables offer the highest level of mechanical protection. They are constructed with a rugged outer jacket and an inner armor, providing superior resistance to physical damage such as crushing or rodent bites. Armoured patch cables are commonly used in demanding applications where additional protection is essential.

IP67 Patch Cables

IP67 patch cables are designed to be water and dust resistant, making them suitable for outdoor use or environments with high moisture levels. These cables provide reliable connectivity even in challenging weather conditions.

MTP/MPO Patch Cables

MTP/MPO patch cables are widely used in data centers and server rooms for high-speed connections. These cables feature multi-fiber connectors, enabling rapid data transmission. They are commonly used in applications that require high bandwidth.

By considering the specific application and requirements of your network, you can choose the right type of patch cable to ensure optimal performance and reliability.

| Types of Patch Cables | Application |

|---|---|

| Duplex Patch Cables | Two-way communication |

| Polarity Twist Cables | Saving space, quick polarity changes |

| Short Boot Patch Cables | Limited space environments |

| Ruggedized Patch Cables | Harsh environments, better mechanical protection |

| Armoured Patch Cables | Extreme conditions, maximum mechanical protection |

| IP67 Patch Cables | Outdoor use, water and dust resistance |

| MTP/MPO Patch Cables | High-speed connections, data centers |

Quality Attributes for Reliable Network Performance

When it comes to fiber patch cable quality, there are several important attributes to consider. Ensuring a reliable network performance relies on factors such as the testing and certification of the cables, the quality control measures applied during manufacturing, and the reputation of the brand. Let’s take a closer look at each of these aspects.

Fiber Patch Cable Testing: Individual Test Reports

One of the key indicators of fiber patch cable quality is the availability of individual test reports. These reports provide valuable information about the performance of each fiber in the cable. Specifically, they indicate whether the fibers have been tested for light attenuation, a crucial factor that directly affects network speed and reliability. By using fiber optic cables with individual test reports, network administrators can have confidence in the performance and longevity of their network infrastructure.

Quality Control in Manufacturing

The production process and quality control measures employed by the manufacturer also play a significant role in ensuring fiber patch cable quality. Reputable brands prioritize rigorous quality control procedures to identify and eliminate any potential defects or inconsistencies in their cable production. These measures often include thorough inspections, adherence to industry standards, and compliance with relevant certifications.

Reputation of Reputable Brands

Choosing a reputable brand, such as ACT, is another important factor in ensuring fiber patch cable quality. Brands that have earned a solid reputation in the industry are known for their commitment to delivering consistent quality products. They invest in research and development, stay up-to-date with the latest technological advancements, and prioritize customer satisfaction. By selecting a reputable brand, network administrators can trust that the fiber patch cables they purchase will meet the highest standards of quality and performance.

By considering these quality attributes and choosing fiber patch cables that adhere to strict testing protocols, manufacturers’ quality control measures, and reputable brands, network administrators can ensure a reliable network performance.

| Fiber Patch Cable Quality Attributes | Benefits |

|---|---|

| Individual Test Reports for Light Attenuation | Assurance of network speed and reliability |

| Quality Control in Manufacturing | Elimination of defects and inconsistencies |

| Reputation of Reputable Brands | Consistent quality and customer satisfaction |

Selecting the Right Patch Cables Based on Fiber Types

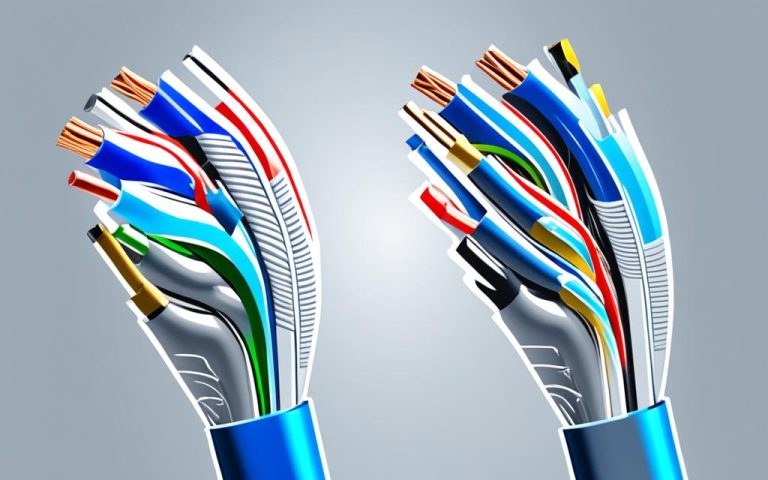

Fiber optic patch cables are available in different types of fibers. It’s important to choose the right fiber type based on your specific application and network requirements. The two main types of fibers used in patch cables are multimode fiber and single mode fiber.

Multimode Fiber

Multimode fiber is commonly used for short distances and has limited speed and length capabilities. It is ideal for applications that use LED or VCSEL light sources. The larger core size of multimode fiber allows for the propagation of multiple modes of light, but it also causes more dispersion and attenuation over long distances. Multimode fiber is often used in LANs, data centers, and premises networks.

Single Mode Fiber

On the other hand, single mode fiber is used for longer distances and offers almost infinite bandwidth. It has a smaller core size and allows only a single mode of light to propagate. This makes it more powerful and accurate, making it ideal for applications that use laser light sources. Single mode fiber provides higher transmission speeds and longer transmission distances, making it suitable for long-haul telecommunications and extensive connectivity.

When selecting the right patch cable based on fiber types, consider factors such as:

- Distance: Determine the distance that needs to be covered by the patch cable.

- Bandwidth: Assess the required bandwidth for your network to ensure optimal performance.

- Application: Consider the specific application and the type of light source being used.

By understanding the characteristics of multimode fiber and single mode fiber, you can choose the right patch cable that meets your network’s needs and ensures reliable connectivity.

| Fiber Type | Distance Capability | Bandwidth | Application |

|---|---|---|---|

| Multimode Fiber | Short distances | Limited | LANs, data centers, premises networks |

| Single Mode Fiber | Long distances | Almost infinite | Long-haul telecommunications, extensive connectivity |

Conclusion

Patch cables are essential for optimizing network performance and ensuring reliable connectivity. By considering factors such as cable category, customization options, and manufacturer reputation, you can make informed decisions when selecting patch cord cables for your network. Understanding the different types of patch cables available, including duplex, short boot, ruggedized, and IP67, allows you to choose the most suitable cable for specific applications. Additionally, paying attention to fiber types and their capabilities enables you to design an optimized network.

Practical knowledge plays a crucial role in ensuring the best patch cable selection for your network. By leveraging this knowledge and making well-informed choices, you can enhance network performance and stability. Patch cable optimization is a key factor in achieving reliable network connectivity.

With patch cables that are carefully selected based on practical knowledge, you can maximize network performance and minimize disruption. By investing in high-quality patch cables and understanding their specific operating characteristics, you can create a network infrastructure that meets the demands of your organization. So, get ready to optimize your network’s performance by applying your practical knowledge in selecting the right patch cables.

FAQ

What are patch cords and why are they important in a network?

Patch cords, also known as Ethernet cables, are essential components in local area networks (LANs) for short-distance network connections. They are used to connect devices like computers, printers, switches, and routers within a network, ensuring reliable connectivity.

What are the different categories of patch cords?

Patch cords come in different categories, such as Cat 5e, Cat 6, Cat 6a, and Cat 7. Each category offers varying levels of performance and data transmission capabilities.

How are patch cords color-coded and why is it important?

Patch cords are color-coded for easy identification. The color coding helps in identifying the type or category of the cable, making it easier to manage and troubleshoot connections within a network.

How do patch cords reduce electromagnetic interference?

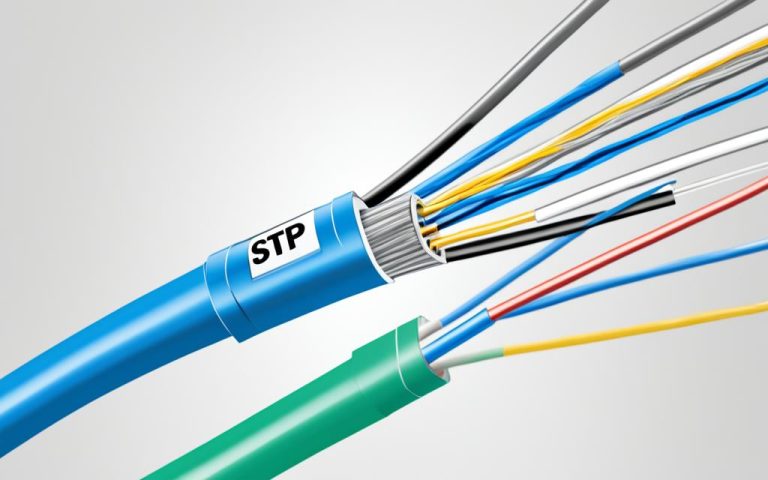

Patch cords have twisted pairs of copper wires inside them, which help reduce electromagnetic interference and ensure a clear signal transmission within a network.

What factors should I consider when choosing a patch cord cable manufacturer?

When selecting a patch cord cable manufacturer, consider factors such as quality and performance of their products, adherence to industry standards, cable category and specifications, customization options, reliability, durability, warranties or guarantees, and the manufacturer’s reputation and track record.

What are the different types of patch cables available for specific applications?

There are various types of patch cables available, including duplex patch cables for two-way communication, polarity twist cables for quick polarity changes and space-saving, short boot patch cables for limited space environments, ruggedized patch cables for better mechanical protection, armoured patch cables for extreme conditions, IP67 patch cables for water and dust resistance, and MTP/MPO patch cables for high-speed connections used in data centers and server rooms.

What quality attributes should I consider for reliable network performance?

When determining the quality of a fiber patch cable, consider factors such as the fiber optic cable grade, individual test reports showing light attenuation testing, the production process and quality control of the manufacturer, and reputable brands known for consistent quality like ACT.

What are the different types of fibers available in fiber optic patch cables?

Fiber optic patch cables are available in two types of fibers: multimode fibers suitable for short distances and applications with LED or VCSEL light sources, and single-mode fibers suitable for longer distances and applications with laser light sources, offering almost infinite bandwidth.

How can I optimize network performance with patch cables?

By considering factors like cable category, customization options, manufacturer reputation, understanding the different types of patch cables available, and selecting the appropriate fiber types, you can optimize network performance and ensure reliable connectivity.