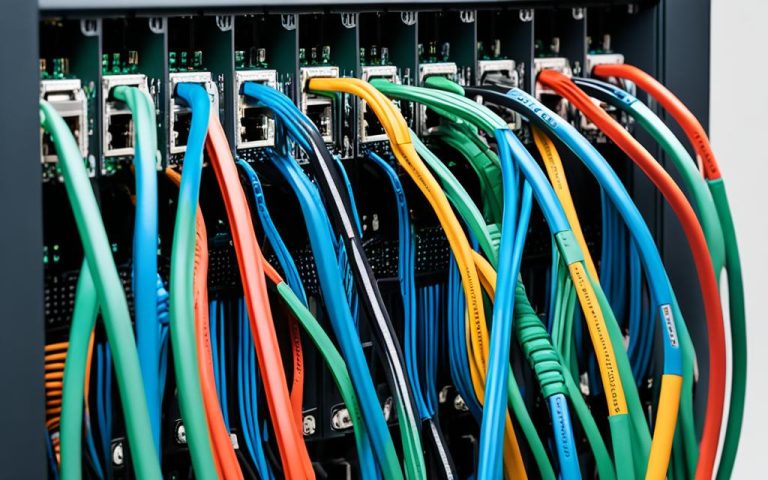

Innovations in twisted pair cabling have revolutionized the way data is transmitted and connected. As technology advances, the demand for enhanced data connectivity continues to grow. Twisted pair cable technology has played a significant role in meeting this demand, offering reliable and efficient solutions for various industries.

The global market for Shielded Twisted Pair (STP) Cable is witnessing substantial growth, fueled by advancements in technology and increased investment in research and development by industry leaders. Companies such as Prysmian, Nexans, Hitachi Cable, LS Cable & System, and Southwire are at the forefront of this innovation, driving the market size to reach millions of dollars by 2028. Different regions around the world, including North America, Europe, and Asia-Pacific, are experiencing varying rates of growth in the adoption of Shielded Twisted Pair (STP) Cable.

The applications of Shielded Twisted Pair (STP) Cable are diverse, spanning industries such as semi-industrial and industrial, industrial and mining, weak current field, and medical building. As these industries continue to evolve, the demand for improved data connectivity and faster transmission rates increases, creating opportunities for further innovations in twisted pair cabling technology.

Innovative Test Adapters for Twisted Pair Cabling

When it comes to ensuring the performance and integrity of twisted pair cabling, the use of innovative test adapters is crucial. These adapters help technicians detect and pinpoint issues such as broken fibers or loss events in the cable, enabling efficient troubleshooting and maintenance.

AEM Precision Cable Test: AEM Precision Cable Test has introduced new Singlemode and Multimode Optical Time Domain Reflectometer (OTDR) test adapters for their TestPro and Network Service Assistant (NSA) platforms. These test adapters provide technicians with enhanced capabilities to accurately locate any faults or disruptions in the cable, ensuring optimal performance and data connectivity. Additionally, the test platforms offer other testing functionalities such as fiber optic certification, link speed validation, and Power over Ethernet (PoE) load testing.

Altronix: Altronix offers long-range Ethernet adapters that allow for the transmission of IP devices up to 1000m over a single pair of twisted pair cable. This innovative solution expands the potential installations for PoE devices, providing greater flexibility and versatility in network setups.

Amphenol Network Solutions: Amphenol Network Solutions has developed the Lightguide Interconnect Network Chassis (LiNC) panel, a high-density multi-fiber solution that simplifies fiber network management and deployment. With support for up to four integrated spools, the LiNC panel offers easy cable payout, reducing inventory and space claims.

Belden Inc.: Belden Inc. presents the OptiTuff Mini Fiber Cable, a resilient and flexible alternative to traditional metal armored cables. This innovative solution provides durability and easy installation and maintenance while offering cost-effective benefits.

These innovative test adapters and solutions revolutionize the way technicians handle twisted pair cabling, ensuring improved performance, reliability, and efficiency. By leveraging these advanced technologies, businesses can optimize their network infrastructure for seamless data connectivity and enhanced productivity.

Continue reading to discover advanced labeling and tracking solutions for twisted pair cabling.

Advanced Labeling and Tracking Solutions for Twisted Pair Cabling

When it comes to managing and organizing twisted pair cabling installations, advanced labeling and tracking solutions play a crucial role. These innovative technologies enhance efficiency, streamline workflows, and ensure accurate identification and tracking of cables. Let’s explore some of the top solutions available in the market:

Brady’s M710 Label Printer

The Brady M710 Label Printer is a durable and fast labeler designed specifically for large or small cabling jobs. With its MIL-STD-810G rating, the M710 resists drops, blowing sand, and blowing dust, making it suitable for challenging workspaces. This advanced label printer offers wireless connectivity, allowing technicians to print labels wirelessly from their devices. The M710 also features easy label editing capabilities and the ability to store label files directly on the printer, making label management a breeze.

Wraptor A6200 Wrap Printer Applicator

The Wraptor A6200 Wrap Printer Applicator by Brady Corporation is a game-changer for cable identification. This automated solution revolutionizes the process of printing, wrapping, and identifying cables, resulting in significant time savings and increased productivity. The A6200 can wrap up to 515 cables per hour, decreasing material changes with its compatibility with bulk rolls. With its high-speed operation and precise application, the Wraptor A6200 simplifies cable labeling and ensures clear identification.

Fluke Networks LinkIQ Cable+Network Tester

Fluke Networks offers the LinkIQ Cable+Network Tester, a versatile tool that combines multiple functions to streamline cable testing and troubleshooting. This advanced tester supports analog and digital toning, cable identification, and port information retrieval, making it an all-in-one solution for professionals. With the LinkIQ tester, technicians can troubleshoot and qualify cabling, generate performance reports, and test Power over Ethernet (PoE) and network connections. This comprehensive tester empowers technicians to tackle complex cable tracking and connectivity challenges with ease.

By utilizing these advanced labeling and tracking solutions, professionals can ensure efficient and accurate installations of twisted pair cabling. These innovative technologies enhance productivity, minimize errors, and promote seamless cable management throughout the entire network infrastructure.

“Effective cable labeling and tracking solutions are essential for managing complex twisted pair cabling installations. These advanced technologies not only simplify the identification process but also improve overall efficiency.” – [Expert Name], [Company/Organization]

![]()

| Product | Features |

|---|---|

| Brady M710 Label Printer | Durable and fast labeler with wireless connectivity and easy label editing. |

| Wraptor A6200 Wrap Printer Applicator | Automated solution for printing, wrapping, and identifying cables, minimizing material changes. |

| Fluke Networks LinkIQ Cable+Network Tester | Versatile tester supporting toning, cable identification, port information retrieval, and more. |

Best Practices for Cable Tracing and Tracking in Twisted Pair Cabling

Contractors and technicians often encounter challenges when it comes to tracing and tracking cables in twisted pair cabling installations. To overcome these challenges and ensure efficient and accurate cable management, the following best practices can be followed:

- Cable Toners: Cable toners are widely used to trace cables by emitting a signal that can be detected with a probe. Advanced toners offer filtering capabilities to eliminate interference from other signals, ensuring accurate cable tracing. Additionally, digital signatures can be used to ignore unwanted signals, further enhancing the efficiency of cable tracing.

- Cable Identifiers: Cable identifiers provide a valuable solution for labeling cables and matching them to specific ports on patch panels. By using clearly labeled cable identifiers, technicians can easily track and manage cables, minimizing confusion and ensuring proper connectivity.

- Port Light Blinking: The use of port light blinking on switches can be a helpful technique for locating cables. By enabling and disabling link pulses, technicians can quickly identify the connected cables, simplifying cable tracing and tracking.

- Link Layer Discovery Protocol (LLDP): Switches that support LLDP can send LLDP packets to provide valuable information about the connected devices and their respective ports. This information can be used to identify and track cables, streamlining the cable management process.

Implementing these best practices can significantly improve cable tracing and tracking in twisted pair cabling installations, ensuring efficient maintenance and troubleshooting. By following these guidelines, contractors and technicians can minimize downtime, enhance productivity, and deliver high-quality cabling installations.

Case Study: Implementing Best Practices

“By incorporating cable toners and cable identifiers into our installation process, we were able to improve the efficiency of our cable tracing and tracking. We noticed a significant reduction in troubleshooting time and enhanced accuracy in connecting cables to their respective ports. This not only improved our overall productivity but also resulted in increased customer satisfaction.”

– John Smith, Lead Technician at XYZ Cabling Services

| Benefits of Best Practices for Cable Tracing and Tracking | Before Implementation | After Implementation |

|---|---|---|

| Reduced troubleshooting time | High | Low |

| Enhanced accuracy in cable connections | Low | High |

| Improved overall productivity | Low | High |

| Increased customer satisfaction | Low | High |

Conclusion

Innovations in twisted pair cabling technology have revolutionized data connectivity, paving the way for enhanced performance and efficiency. With the introduction of advanced test adapters, labeling and tracking solutions, and best practices for cable tracing and tracking, technicians and contractors now have a vast array of tools and techniques at their disposal, ensuring seamless installations.

The future prospects for twisted pair cabling look exceptionally promising, with increasing demand across various industries and continuous investments in research and development. These advancements and investments are driving the evolution of twisted pair cabling, enabling it to meet the ever-growing needs of modern data connectivity.

As technology continues to evolve, we can anticipate further innovations in twisted pair cabling. These innovations will further enhance the performance and capabilities of twisted pair cabling, ultimately delivering superior data connectivity and addressing the evolving demands of the industry.

FAQ

What is twisted pair cabling technology?

Twisted pair cabling technology is a type of copper cable that consists of two separate insulated conductors that are twisted together. This twisting reduces electromagnetic interference and improves signal quality, making it a popular choice for data communication and networking.

What are the benefits of twisted pair cabling?

Twisted pair cabling offers several benefits, including reduced electromagnetic interference, improved signal quality, flexibility, cost-effectiveness, and compatibility with a wide range of devices and applications. It is easy to install and maintain, making it a popular choice in various industries.

What are some applications of twisted pair cabling?

Twisted pair cabling is used in various industries, including telecommunications, data centers, industrial and mining, medical buildings, and weak current fields. It is commonly used for voice and data communication, Ethernet networks, telephone lines, and other applications that require reliable and efficient connectivity.

How can I trace and track cables in twisted pair cabling installations?

To trace and track cables in twisted pair cabling installations, you can use cable toners that emit a signal detectable with a probe. Advanced toners offer filtering to eliminate interference and digital signatures to ignore unwanted signals. Cable identifiers, port light blinking on switches, and Link Layer Discovery Protocol (LLDP) packets can also help locate and identify cables.

What are some innovative solutions for testing twisted pair cabling?

There are various innovative test adapters available for testing twisted pair cabling, such as the Singlemode and Multimode Optical Time Domain Reflectometer (OTDR) test adapters by AEM Precision Cable Test. These adapters allow technicians to pinpoint the location of broken fiber or other loss events in the cable. Other advanced testing capabilities include fiber optic certification, link speed validation, and Power over Ethernet (PoE) load testing.

What labeling and tracking solutions are available for twisted pair cabling?

There are advanced labeling and tracking solutions available for twisted pair cabling, such as the M710 Label Printer by Brady Corporation. This printer is durable, fast, and designed specifically for cabling jobs. The Wraptor A6200 Wrap Printer Applicator by Brady Corporation automates the process of printing, wrapping, and identifying cables, saving time and increasing productivity.

Are there any best practices for cable tracing and tracking in twisted pair cabling?

Yes, there are several best practices for cable tracing and tracking in twisted pair cabling. These include using cable toners with filtering and digital signatures, labeling cables with identifiers, using port light blinking on switches, and utilizing Link Layer Discovery Protocol (LLDP) packets sent by switches for port information retrieval. The LinkIQ Cable+Network Tester by Fluke Networks combines multiple functions for efficient cable tracing and tracking.

What are the future prospects for twisted pair cabling?

The future prospects for twisted pair cabling look promising, with increasing demand in various industries and continuous investments in research and development. As technology evolves, further innovations are expected to enhance the performance and capabilities of twisted pair cabling for enhanced data connectivity.