Twisted pair cabling plays a crucial role in industrial networks, facilitating reliable data transmission and communication. It finds applications in various industrial settings, contributing to the efficiency and robustness of communication systems. These cables are extensively used in telephone lines, local area networks (LANs), and Digital Subscriber Line (DSL) connections.

Twisted pair cables are composed of insulated copper wires twisted together, which helps minimize electromagnetic radiation, reduce interference, and provide better noise immunity. They come in different categories, such as unshielded twisted pair (UTP) and shielded twisted pair (STP), each offering distinct advantages and suitability for specific industrial applications.

Twisting in twisted-pair cables reduces noise, signal interference, and crosstalk, enhancing the overall performance and robustness of industrial networks. The choice of twisted pair cables in industrial applications depends on factors like data rate, transmission distance, and noise immunity requirements. By leveraging the benefits of twisted pair cabling, industrial networks can achieve efficient and reliable communication, contributing to the overall productivity and success of industrial operations.

Twisted Pair Cabling Systems: Categories and Types

Twisted pair cabling systems play a crucial role in industrial networks, providing reliable data transmission and communication. These systems can be classified into different categories based on their shielding capabilities. The two primary categories are unshielded twisted pair (UTP) and shielded twisted pair (STP).

UTP cables are widely used in various industrial applications, such as Ethernet networks, telephone systems, and DSL lines. They are favored for their low cost, ease of installation, and flexibility. UTP cables consist of multiple pairs of insulated copper wires twisted together, offering reliable performance and noise reduction.

On the other hand, STP cables provide enhanced resistance to noise and signal interference. They are more durable and have better shielding properties compared to UTP cables. However, due to their additional shielding, they are generally more challenging to terminate and relatively more expensive.

Twisted pair cables are further classified into different types, each catering to specific industrial networking requirements. Here are some common types of twisted pair cables:

- Cat5e: This type of cable supports data rates of up to 1000 Mbps and is suitable for Ethernet networks.

- Cat6: Cat6 cables offer higher performance and can handle data rates of up to 10 Gbps. They are commonly used in industrial applications that require faster transmission speeds.

- Cat6a: Cat6a cables are an enhanced version of Cat6, capable of supporting data rates of up to 10 Gbps over longer distances. They are suitable for high-speed industrial networks.

- Cat7a: Cat7a cables provide excellent performance and can support data rates of up to 10 Gbps over distances of up to 100 meters. They offer superior noise immunity and are ideal for demanding industrial applications.

The choice of twisted pair cable type depends on the specific requirements of the industrial application, such as data rate, distance, and noise immunity. By selecting the appropriate category and type, industrial networks can ensure efficient and reliable data transmission, contributing to the overall success of industrial operations.

| Category | Application | Data Rate | Distance |

|---|---|---|---|

| Cat5e | Ethernet networks | 1000 Mbps | 100 meters |

| Cat6 | Industrial networks | 10 Gbps | 55 meters |

| Cat6a | High-speed industrial networks | 10 Gbps | 100 meters |

| Cat7a | Demanding industrial applications | 10 Gbps | 100 meters |

Why Choose Twisted Pair Cabling Systems?

Twisted pair cabling systems offer a range of benefits for industrial networks:

- Reliable data transmission: Twisted pair cables provide reliable data transmission, minimizing the risk of signal loss and disruption.

- Noise reduction: The twisting effect in these cables helps cancel out electromagnetic fields and reduces crosstalk, resulting in better signal quality and noise immunity.

- Flexibility: Twisted pair cables are flexible and easy to install, making them suitable for various industrial applications.

- Cost-effective: UTP cables, in particular, are cost-effective, offering a budget-friendly solution for industrial networking needs.

- High-speed capabilities: Twisted pair cables can support high data transfer speeds, enabling efficient communication in industrial networks.

With their shielding capabilities, different categories, and types, twisted pair cabling systems provide a versatile and reliable solution for industrial networking requirements. The careful selection of the appropriate category and type ensures optimal performance and data transmission in various industrial applications.

Twisted Pair Cables in Industrial Networking Applications

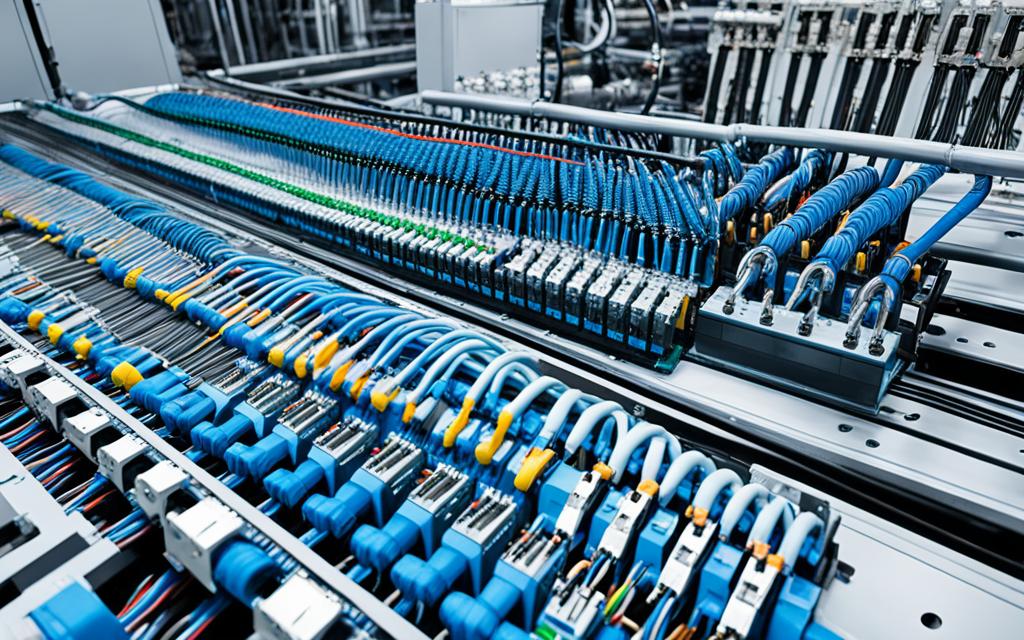

Twisted pair cables play a crucial role in industrial networking applications, contributing to the robustness and efficiency of communication systems. These cables find extensive usage in various industrial settings due to their reliability and high-speed data transmission capabilities.

One of the primary applications of twisted pair cables in industrial networking is in Ethernet networks. They are commonly used to connect computers, routers, switches, and other network devices within Local Area Networks (LANs). These cables ensure reliable and fast data transmission, making them suitable for home, office, and data center networks.

Twisted pair cables are also widely utilized in telephone systems. They support both landline connections and Voice over IP (VoIP) technologies, enabling clear and uninterrupted communication in industrial environments. In addition, these cables play a significant role in security and surveillance systems by facilitating the transmission of video signals from surveillance cameras to control rooms.

Furthermore, twisted pair cables are essential components in building automation and control systems. They enable the seamless communication and control of various devices and sensors within industrial facilities, contributing to enhanced efficiency and productivity.

Twisted pair cables also find applications in audio and entertainment systems in industrial settings. They facilitate the transmission of audio signals, ensuring high-quality sound and reliable performance. Additionally, these cables play a vital role in industrial control and automation applications, enabling the seamless exchange of data between different control systems and devices.

Applications of Twisted Pair Cables in Industrial Networking

| Application | Description |

|---|---|

| Ethernet Networks | Connectivity for computers, routers, switches, and network devices in LANs. |

| Telephone Systems | Support landline connections and Voice over IP (VoIP) technologies. |

| Security and Surveillance Systems | Enable video signal transmission from surveillance cameras to control rooms. |

| Building Automation and Control Systems | Seamless communication and control of devices and sensors in industrial facilities. |

| Audio and Entertainment Systems | Transmission of audio signals for high-quality sound in industrial settings. |

| Industrial Control and Automation | Data exchange between control systems and devices for efficient automation. |

Overall, twisted pair cables have a wide range of applications in industrial settings, enhancing the reliability and efficiency of communication systems. Their versatility and performance make them an indispensable component in industrial networking.

Advantages of Twisted Pair Cables in Industrial Networks

Twisted pair cables play a vital role in industrial networks, offering numerous benefits and advantages. These cables are specifically engineered to provide reliable data transmission and communication in challenging industrial environments. Let’s explore the advantages of using twisted pair cables in industrial applications:

Noise Resistance and Reliable Data Transmission

One of the significant advantages of twisted pair cables is their excellent noise resistance. The twisting effect in these cables helps to cancel out electromagnetic fields and minimize crosstalk, resulting in better signal quality and lower attenuation. This noise resistance ensures reliable data transmission, reducing the risk of interference and data loss, which is critical for industrial networks’ smooth operations.

Flexibility and Cost-effectiveness

Twisted pair cables are highly flexible, making them easy to install and maneuver in complex industrial setups. They can be easily cut to required lengths and terminated with standard connectors, simplifying the installation process. Additionally, twisted pair cables are cost-effective compared to other types of cables, providing industrial networks with a cost-efficient solution for their communication needs.

High Data Transfer Speeds

Another advantage of twisted pair cables is their capability to support high data transfer speeds. Depending on the cable category and type, twisted pair cables can achieve data rates ranging from 1 Gbps to 10 Gbps. This high-speed data transmission is crucial for industrial applications that require real-time data monitoring, remote control, and fast communication between interconnected devices.

Backward Compatibility

Twisted pair cables are designed to be backward compatible, allowing for seamless integration with existing infrastructure. This compatibility ensures that industrial networks can easily upgrade their communication systems without the need for significant infrastructure changes. It provides a cost-efficient and flexible solution for future network expansions and upgrades.

Versatility and Wide-ranging Applications

Twisted pair cables find widespread applications in various industrial sectors. They are commonly used in Ethernet networks, telephone systems, security and surveillance systems, building automation and control systems, audio systems, and industrial control and automation applications. The versatility of twisted pair cables makes them a popular choice in industrial networking, enabling efficient and reliable communication across diverse industrial applications.

Overall, the advantages of twisted pair cables in industrial networks are significant. They provide excellent noise resistance, reliable data transmission, flexibility, and cost-efficiency. With their high data transfer speeds, backward compatibility, and wide-ranging applications, twisted pair cables are a reliable choice for industrial networking needs.

Advantages of Twisted Pair Cables

| Advantage | Description |

|---|---|

| Noise Resistance | Twisting effect cancels out electromagnetic fields and reduces crosstalk, ensuring reliable data transmission |

| Flexibility | Easy installation and maneuverability in complex industrial setups |

| Cost-effectiveness | Provides a cost-efficient solution for industrial communication needs |

| High Data Transfer Speeds | Supports high-speed data transmission, ranging from 1 Gbps to 10 Gbps |

| Backward Compatibility | Seamless integration with existing infrastructure, allowing for easy upgrades |

| Versatility | Wide-ranging applications in various industrial sectors |

Considerations for Choosing Twisted Pair Cables in Industrial Applications

When selecting twisted pair cables for industrial applications, several factors need to be considered. By taking into account the specific requirements of the application, such as data rate, transmission distance, and noise immunity, you can make an informed decision and choose the most suitable cable category and type.

Data Rate: The required speed of data transmission is a crucial consideration when choosing twisted pair cables. Higher data rates may necessitate the use of Cat6 or Cat6a cables, which can support faster transmission speeds compared to lower category cables.

Transmission Distance: The distance over which the data needs to be transmitted is another important factor. Different twisted pair cable types have varying distance limitations. It is essential to select a cable that can reliably transmit data over the required distance without signal degradation.

Noise Immunity: In industrial environments, there can be a significant amount of electrical noise and interference. If your application is prone to noise, it is advisable to choose shielded twisted pair (STP) cables. STP cables provide better resistance to noise and interference compared to unshielded twisted pair (UTP) cables, ensuring more reliable data transmission.

Installation Environment: The installation environment plays a crucial role in determining the durability and reliability of twisted pair cables. Factors such as temperature extremes, moisture, and exposure to chemicals or oils should be taken into account. Considering these factors will help ensure that the chosen cables can withstand the specific environmental conditions of your industrial application.

Cost: Cost is an important consideration for any project. It is essential to evaluate the cost of twisted pair cables in relation to their performance and suitability for your industrial application. While it may be tempting to choose the most affordable option, it is crucial to balance cost with the required performance and durability.

Ease of Installation and Future Scalability: The ease of installation and future scalability of twisted pair cables should also be considered. Choosing cables that are easy to install can save time and effort during the installation process. Additionally, considering future scalability can help ensure that the chosen cables can accommodate any future expansions or upgrades to your industrial network.

By carefully considering these factors, you can choose the most appropriate twisted pair cables for your industrial networking needs. Whether it’s selecting the right category and type of cable based on data rate and transmission distance, prioritizing noise immunity in noisy environments, considering the installation environment, calculating the cost-effectiveness, or evaluating ease of installation and future scalability, making informed decisions will contribute to the efficiency and reliability of your industrial network.

Conclusion

Twisted pair cabling plays a vital role in industrial networks, providing reliable data transmission, superior noise resistance, and enhanced flexibility. With its wide range of industrial applications, including Ethernet networking, telephone systems, security and surveillance systems, building automation and control, audio systems, and industrial control and automation, twisted pair cables have become an essential component in modern industrial operations.

These cables are available in various categories and types, each tailored to specific requirements and offering distinct advantages. By considering factors such as data rate, transmission distance, noise immunity, installation environment, and cost, businesses can select the most suitable twisted pair cables for their industrial applications, ensuring optimal performance and efficiency.

By harnessing the benefits of twisted pair cabling, industrial networks can achieve robust and efficient communication, ultimately contributing to the overall productivity and success of industrial operations. With reliable data transmission, noise resistance, and flexibility, twisted pair cabling empowers industrial environments to meet the demands of modern communication systems and ensure seamless connectivity.

FAQ

What are twisted pair cables?

Twisted pair cables are composed of insulated copper wires that are twisted together. This twisting helps to minimize electromagnetic radiation, reduce interference, and provide better noise immunity.

What are the different categories of twisted pair cables?

Twisted pair cables come in different categories, ranging from Cat1 to Cat8. Each category offers distinct advantages and suitability for specific industrial applications.

What are the advantages of unshielded twisted pair (UTP) cables?

UTP cables are commonly used in Ethernet networks, telephone systems, and DSL lines due to their low cost, ease of installation, and flexibility.

What are the advantages of shielded twisted pair (STP) cables?

STP cables provide better resistance to noise and signal interference but are more challenging to terminate and relatively more expensive.

What are the different types of twisted pair cables?

Twisted pair cables are further classified into various types, including Cat5e, Cat6, Cat6a, and Cat7a. Each type is capable of supporting different transmission speeds and distances.

What are the applications of twisted pair cables in industrial networking?

Twisted pair cables are commonly used in Ethernet networks within Local Area Networks (LANs) to connect computers, routers, switches, and other network devices. They are also used in telephone systems, security and surveillance systems, building automation and control systems, audio and entertainment systems, and industrial control and automation applications.

What are the advantages of twisted pair cables in industrial networks?

Twisted pair cables offer excellent noise resistance, reduce interference and crosstalk, provide high data transfer speeds, are flexible and cost-effective, and are backward-compatible with existing infrastructure.

What factors should be considered when choosing twisted pair cables for industrial applications?

When selecting twisted pair cables, factors such as data rate, transmission distance, noise immunity, installation environment, durability, reliability, cost, ease of installation, and future scalability should be taken into account.