Designing a custom cable solution for specialized applications requires a deep understanding of the specific requirements and environmental factors involved. Factors such as the end application, application environment, time, temperature, frequency, concentration, and critical-to-quality characteristics all need to be taken into consideration. The complexity of designing a custom cable solution may seem overwhelming, but partnering with a cable design engineer can ensure the selection of the right solution.

Prototyping may be necessary for new projects to test the performance of the cable solution. The choice of copper stranding, such as bare copper, copper alloys, and coatings like tin, nickel, and silver, is an important consideration. The size and configuration of the copper stranding depend on the specific application’s requirements, as different designs impact flexibility and movement requirements.

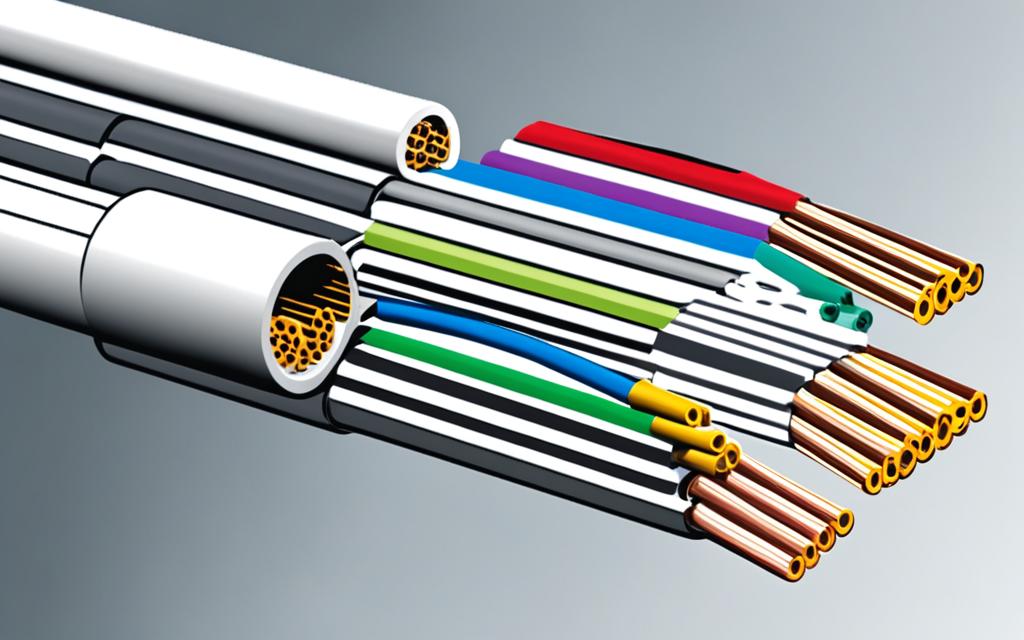

Conductors can be made of various materials, including bare copper, tin-plated copper, silver-plated copper, nickel-plated copper, alloys, steel, tinsel wire, and fiber optic. The choice of conductor material depends on factors such as conductivity, cost, temperature rating, corrosion resistance, and flexibility.

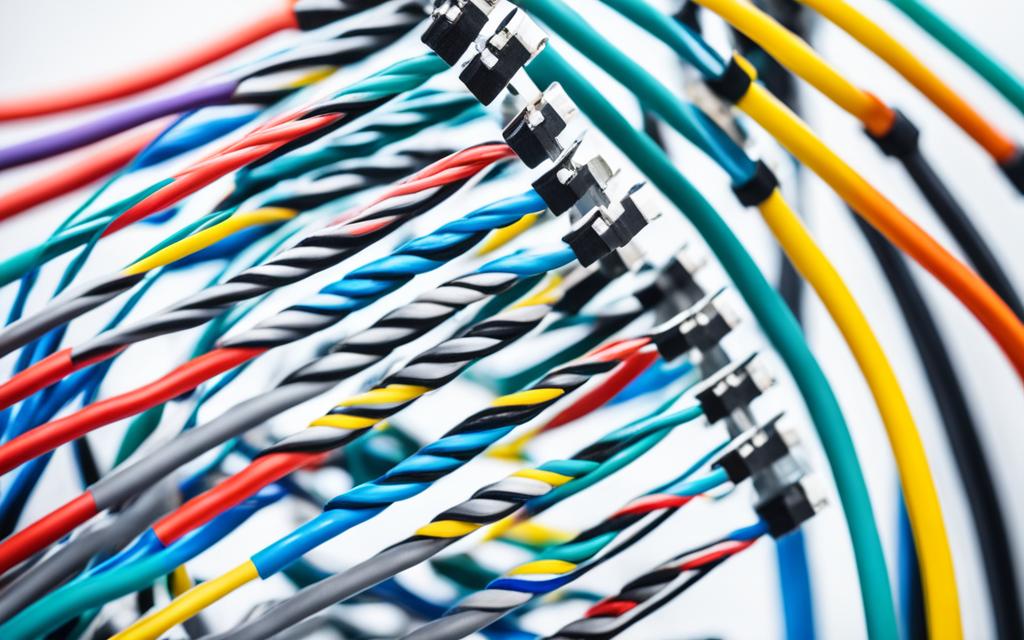

Shielding, filling, and wrapping materials also play a crucial role in cable design, reducing interference, increasing flex life, and acting as barriers. Materials such as foil, tape, wraps, and fillers offer various properties and strengths for cable design.

By collaborating with a cable design engineer, organizations can ensure the development of custom twisted pair solutions that meet their specialized cabling needs.

Materials and Configurations for Custom Twisted Pair Cables

Choosing the right materials for custom twisted pair cables is essential. Different materials offer unique benefits and suitability for various applications. Conductors, for example, can be made of:

- Bare copper

- Tin-plated copper

- Silver-plated copper

- Nickel-plated copper

- Alloys

- Steel

- Tinsel wire

- Fiber optic

Each conductor material possesses specific characteristics that must be considered when selecting the most suitable material. Factors such as conductivity, cost, temperature rating, corrosion resistance, and flexibility play a crucial role in determining the ideal conductor material for a given custom cable design.

Shielding materials are also vital in reducing interference and ensuring optimal performance. Materials like foil and braids are used to shield twisted pair cables. Different materials and configurations provide varying levels of shielding effectiveness and flex life. Tapes, wraps, and fillers can be utilized to further enhance flex life, protect against cross-talk, and create barriers between cable components and outer jackets.

The selection of materials and configurations depends on the specific requirements of the custom cable design, considering factors such as the application’s environment and the desired performance and functionality.

Benefits of Different Conductor Materials

Here are some benefits associated with different conductor materials:

| Conductor Material | Benefits |

|---|---|

| Bare copper | Excellent conductivity and cost-effectiveness |

| Tin-plated copper | Improved corrosion resistance |

| Silver-plated copper | Enhanced conductivity and corrosion resistance |

| Nickel-plated copper | High resistance to corrosion and temperature extremes |

| Alloys | Combination of desired properties from different metals |

| Steel | Increased strength and durability |

| Tinsel wire | Flexible and resistant to fatigue |

| Fiber optic | High-speed data transmission over longer distances |

Applications and Grades of Twisted Pair Cables

Twisted pair cables, both shielded (STP) and unshielded (UTP), are widely used in LANs today. UTP cables typically have eight separate conductors placed in four pairs of twisted conductors. This configuration inhibits interference and acts as a buffer against external interference. UTP cables are primarily used in LANs, while STP cables were originally developed for Token Ring networks.

UTP cable grades, such as Category 3 and Category 5, are defined by the Electronics Industry Association (EIA) and the Telecommunications Industry Association (TIA). Category 3 cables are suitable for 10 Mbps Ethernet networks, while Category 5 cables are best suited for 100BaseTX Fast Ethernet networks running at 100 Mbps. Other UTP cable grades, such as Level 5, offer increased bandwidth and can support Gigabit Ethernet protocols.

STP cables also have different grades, including Type 1A and Type 6A, which are used in Token Ring networks. The choice of twisted pair cable grades depends on the specific requirements of the application.

Benefits of Custom Multi-Conductor Cables

Custom multi-conductor cables provide numerous benefits for specific projects, offering tailored solutions for optimal performance and functionality. Here are some key advantages of customizing multi-conductor cables:

Wire Consolidation

One primary benefit of custom multi-conductor cables is the ability to consolidate multiple cable legs into a single main cable trunk. This consolidation streamlines cable routing and simplifies installation, reducing clutter and improving overall efficiency. By consolidating wires, organizations can achieve a more organized and streamlined system, enhancing maintenance and troubleshooting processes.

Customization of Shielding, Drain Wires, and Twisted Pairs

Custom multi-conductor cables can be tailored to include specific shielding, drain wires, and twisted pairs, allowing for customization of shielding provisions based on the desired program objectives. The exact placement and combination of shielding, drain wires, and twisted pairs can be customized to meet the specific design requirements. This customization ensures optimum performance, noise suppression, and protection against interference, ensuring reliable and high-quality signal transmission.

Cost and Lead Time Reduction

By opting for custom multi-conductor cables, organizations can reduce costs and lead time compared to using separate wires and cables. Customization allows for the creation of a consolidated cable that meets specific requirements, eliminating the need for multiple individual cables. This not only reduces material costs but also simplifies inventory management and installation processes. Additionally, customization reduces lead time by eliminating the need for sourcing and assembling multiple components separately.

Enhanced Flexibility in Design

Custom multi-conductor cables offer design flexibility by allowing for the bespoke combination of shielding, drain wires, and twisted pairs. This flexibility ensures that the cable design meets the specific needs of the application, providing the necessary strength, flexibility, and noise suppression. Organizations can optimize the cable design to achieve the desired performance and functionality, tailored to their unique requirements.

“Custom multi-conductor cables offer design flexibility, wire consolidation, and customization of shielding, drain wires, and twisted pairs, enabling optimized performance and functionality for specialized applications.”

Furthermore, customization provides the opportunity to integrate additional features and specifications into the cable design, such as special insulation materials, environmental durability, or specific temperature ratings. This enables organizations to meet the stringent requirements of their applications, ensuring reliable and long-lasting cable solutions.

Overall, custom multi-conductor cables offer a range of benefits, including wire consolidation, customization of shielding, drain wires, and twisted pairs, cost and lead time reduction, and enhanced flexibility in design. These advantages make custom multi-conductor cables an ideal choice for organizations seeking tailored, efficient, and reliable cable solutions for their specialized applications.

Installation and Considerations for Twisted Pair Cables

Installing twisted pair cables requires careful planning and consideration. It is crucial to engage qualified cable installers with expertise in telephone and LAN cable installations. The flexibility of UTP cables makes them easier to work with during installation compared to coaxial cables.

The installation process involves several important steps:

- Properly routing and organizing the cables to ensure efficient transmission and prevent tangling or damage.

- Terminating the cables with RJ-45 connectors to establish a secure and reliable connection.

- Ensuring compliance with industry standards, such as EIA/TIA categories, which define the performance requirements for different grades of cables.

When installing UTP cables, the choice of grade depends on the required network speeds. Category 3 and Category 5 grades are commonly used for LAN installations, with Category 5 supporting faster network speeds, such as 100 Mbps. In applications where electromagnetic interference is a concern, shielded twisted pair (STP) cables, such as Type 1A and Type 6A, are used.

Proper installation techniques, adherence to standards, and attention to detail are critical for the successful deployment of twisted pair cables. By ensuring a professional installation, organizations can maximize the performance and reliability of their LAN infrastructure.

Customizing Twisted Pair Cables for Specific Applications

Customization plays a vital role in designing twisted pair cables that meet the unique requirements of specific applications. To ensure optimal performance and functionality, the design process begins by precisely defining the wire size, conductor count, and shielding methodology based on the application’s needs.

One of the key advantages of custom multi-conductor cables is the ability to consolidate multiple cable legs into one main cable trunk. This consolidation simplifies cable routing and installation, reducing complexity and saving valuable time and effort.

Furthermore, customization allows for the tailoring of shielding provisions, drain wires, and twisted pairs to suit the desired program objectives. By incorporating the right combination of these elements, custom twisted pair cables can provide the necessary strength, flexibility, and noise suppression required for the application.

Partnering with a full-service manufacturing partner is crucial for successful customization. They can assist throughout the design review, fabrication, termination, and electrical testing processes, ensuring the final custom twisted pair cables meet the specific requirements with precision and reliability.

To highlight the customization options available, consider the following table:

| Customization Element | Description |

|---|---|

| Shielding | Customize the shielding type and configuration to enhance electromagnetic interference (EMI) protection for the cable. |

| Drain Wires | Include drain wires to facilitate the grounding of the cable and minimize the impact of noise on signal quality. |

| Twisted Pairs | Specify the number and configuration of twisted pairs to optimize the cable’s noise-cancelling capability and improve performance. |

| Wire Size and Conductor Count | Customize the wire size and conductor count for proper signal transmission, taking into account factors such as distance and power requirements. |

By leveraging the customization options available, designers can ensure that the twisted pair cables meet the specific application requirements, resulting in a reliable and efficient solution for various industries and sectors.

Advantages of Twisted Pair Cables over Coaxial Cables

Twisted pair cables have revolutionized data networking, offering significant advantages over traditional coaxial cables. Both Unshielded Twisted Pair (UTP) and Shielded Twisted Pair (STP) cables provide increased flexibility, making them easier to install and work with. The smaller size of twisted pair cables allows for convenient cable routing, even in tight spaces.

One of the key advantages of twisted pair cables is their ability to resist interference. With multiple pairs of twisted conductors, UTP cables inhibits interference from other wire pairs and external sources, resulting in improved signal quality and reduced noise levels.

Twisted pair cables act as a buffer against external interference, ensuring reliable data transmission and protecting data integrity.

Compared to coaxial cables, twisted pair cables offer superior cost-effectiveness without compromising on performance. Additionally, advancements in UTP cable grades have enabled higher data transfer rates, making them ideal for applications that require fast and reliable connectivity, such as Gigabit Ethernet.

In summary, the advantages of twisted pair cables over coaxial cables include:

- Flexibility: Ease of installation and better maneuverability in tight spaces.

- Interference resistance: Multiple twisted pairs that inhibit interference, resulting in improved signal quality.

- Cost-effectiveness: A more affordable option compared to coaxial cables, without compromising on performance.

These advantages make twisted pair cables the preferred choice for LANs and other data networking applications.

Conclusion

Designing custom twisted pair cabling for specialized applications requires a comprehensive understanding of the application’s requirements and environmental factors. By partnering with a cable design engineer and utilizing custom twisted pair solutions, organizations can ensure the development of reliable and high-performing cabling systems tailored to their specialized needs.

Customization is the key to achieving optimal performance and functionality in custom twisted pair cables. It allows for the selection of specific materials, configurations, and grades of cables that best meet the desired requirements. Custom multi-conductor cables offer additional benefits, such as wire consolidation and customization of shielding, drain wires, and twisted pairs, providing a streamlined and efficient solution.

Installation of twisted pair cables requires careful planning and adherence to industry standards. By following proper installation techniques and standards, organizations can ensure a successful deployment that maximizes the advantages of twisted pair cables. These cables offer advantages over coaxial cables, including superior flexibility, ease of installation, and resistance to interference.

In conclusion, custom twisted pair solutions offer the flexibility and performance needed for specialized applications. With careful custom cable design, organizations can optimize the functionality, reliability, and efficiency of their cabling systems, ultimately supporting the success of their projects and operations.

FAQ

What factors need to be considered when designing custom cables?

The factors that need to be considered when designing custom cables include the end application, application environment, time, temperature, frequency, concentration, and critical-to-quality characteristics.

Why is partnering with a cable design engineer important for custom cable design?

Partnering with a cable design engineer is important for custom cable design because they have the expertise and knowledge to ensure the right cable solution is chosen for the specific end application.

Why are prototyping and testing necessary for new projects?

Prototyping and testing are necessary for new projects to evaluate the performance of the cable solution and ensure it meets the requirements of the application.

What are the considerations for copper stranding in custom cable design?

The considerations for copper stranding in custom cable design include the options of bare copper, copper alloys, and coatings like tin, nickel, and silver. The size and configuration of the copper stranding depend on the specific requirements of the application.

What are the different materials that can be used for conductors in custom cables?

The different materials that can be used for conductors in custom cables include bare copper, tin-plated copper, silver-plated copper, nickel-plated copper, alloys, steel, tinsel wire, and fiber optic.

What role do shielding, filling, and wrapping materials play in cable design?

Shielding, filling, and wrapping materials play a crucial role in reducing interference, increasing flex life, and acting as barriers in cable design.

What are the different grades of UTP cables?

The different grades of UTP cables include Category 3, Category 5, and Level 5, each suitable for different network speeds and protocols.

What are the benefits of custom multi-conductor cables?

The benefits of custom multi-conductor cables include the ability to consolidate multiple cable legs, customization of shielding and twisted pairs, cost and lead time reduction, and the creation of a more efficient solution for specialized applications.

What is involved in the installation of twisted pair cables?

The installation of twisted pair cables involves careful planning, proper routing and organizing of cables, termination with RJ-45 connectors, and compliance with industry standards.

How can custom twisted pair cables be designed for specific applications?

Custom twisted pair cables can be designed for specific applications by carefully defining the wire size, conductor count, shielding methodology, and customization of shielding provisions based on the application’s requirements.

What advantages do twisted pair cables have over coaxial cables?

Twisted pair cables offer advantages such as increased flexibility, easier installation, resistance to interference, and cost-effectiveness compared to coaxial cables.

How can organizations ensure the development of reliable and high-performing cabling systems?

Organizations can ensure the development of reliable and high-performing cabling systems by partnering with a cable design engineer and utilizing custom twisted pair solutions tailored to their specialized needs.