Welcome to our comprehensive guide on optical fiber installation and maintenance best practices. Fiber optic cables are at the forefront of modern communication networks, providing superior performance and reliability compared to traditional copper cables. However, to fully harness the benefits of fiber optic technology, it is crucial to follow proper installation and maintenance procedures. In this article, we will explore the essential guidelines and tips that will ensure the seamless functioning of your optical fiber network. Whether you are new to fiber optic installation or seeking to improve your existing infrastructure, this installation guide and maintenance tips will provide you with expert insights and proven strategies for success.

Determining Cable Length and Planning

Before installing fiber optic cables, it is important to accurately determine the required cable length. Proper cable length measurement ensures efficient installation and avoids unnecessary wastage. To determine the cable length:

- Measure your facility carefully, considering any additional lengths required for corners, vertical installations, and non-linear connections.

- Take into account any obstacles or constraints that may affect cable routing, such as walls or conduits.

- Consider future expansion or changes in the network layout when calculating the required cable length.

It is advisable to order extra lengths to allow for slack and accommodate any unanticipated needs during installation.

Creating a port map is another crucial aspect of planning for your fiber optic installation. A port map is a detailed diagram that specifies the name of each port, its connection, and the location of network cabinets and patch panels. This map serves as a reference for efficient installation and makes future maintenance and troubleshooting easier. By having a clear port map, technicians can quickly identify the exact location of any cable or connection, simplifying the management of the network infrastructure.

Example Port Map:

| Port Name | Connection | Network Cabinet |

|---|---|---|

| Port 1 | Switch 1 / Patch Panel A1 | Network Cabinet A |

| Port 2 | Switch 1 / Patch Panel A2 | Network Cabinet A |

| Port 3 | Switch 2 / Patch Panel B1 | Network Cabinet B |

| Port 4 | Switch 2 / Patch Panel B2 | Network Cabinet B |

Having a comprehensive port map enables the systematic organization and labeling of your network infrastructure, making it easier to troubleshoot, perform upgrades, and ensure efficient cable management.

By accurately determining cable length and creating a detailed port map, you can streamline your fiber optic installation process, minimize wastage, and make future maintenance more efficient.

Adhering to Cable Ratings and Best Practices

When it comes to fiber optic cable installation, adhering to cable ratings and following best practices is essential for optimal performance and preventing damage. Paying attention to factors such as tensile load rating, pull length, cable bend radius, cable lubrication, and cable management can significantly impact the longevity and reliability of your fiber optic network.

Understanding Tensile Load Rating and Pull Length

Fiber optic cables come with specific ratings for tensile load, which indicate the maximum amount of force the cable can withstand without sustaining damage. It is crucial to follow these ratings strictly during installation to avoid overloading the cables and compromising their performance. Additionally, determining the appropriate pull length is vital to prevent unnecessary strain and potential breakage of the fibers.

Maintaining the Cable Bend Radius

Exceeding the recommended cable bend radius can lead to fiber breakage and signal loss. It is important to understand the bend radius requirements for the specific type of fiber optic cable being installed and ensure that it is not exceeded during the installation process. By adhering to the proper bend radius guidelines, you can safeguard the integrity of the fibers and maintain optimal signal transmission.

“Exceeding the recommended cable bend radius can lead to fiber breakage and signal loss.”

Using Cable Lubrication

When pulling cables through conduits or trays, friction can cause tension and lead to potential damage. To minimize the risk of cable breakage and ensure smooth installation, it is recommended to use cable lubricant. Applying lubricant helps reduce tension, prevent snags, and protect the cable during the pulling process.

Effective Cable Management

Cable management plays a vital role in organizing and securing fiber optic cables. Properly managing and securing cables not only ensures a neat and tidy installation but also protects them from accidental damage. Implementing cable management solutions like cable trays, racks, and ties help maintain cable integrity and facilitates ease of maintenance and troubleshooting.

Visualizing Cable Ratings and Best Practices

| Cable Rating | Best Practice |

|---|---|

| Tensile Load Rating | Follow the specified rating to prevent cable damage. |

| Pull Length | Determine the appropriate pull length to avoid strain. |

| Cable Bend Radius | Adhere to the recommended bend radius to prevent fiber breakage. |

| Cable Lubrication | Use cable lubricant when pulling cables to reduce tension. |

| Cable Management | Implement effective cable management solutions for organization and protection. |

By strictly adhering to cable ratings, following best practices, and implementing proper cable management, you can ensure the longevity and optimal performance of your fiber optic network. Keep in mind that negligence in any of these areas can lead to cable damage, signal loss, and costly repairs. Taking the time to understand and implement these guidelines will contribute to the smooth operation and reliability of your fiber optic infrastructure in the long run.

Handling and Care Tips

Fiber optic cables and connectors are delicate components that require careful handling to prevent damage and ensure optimal performance. By following these handling and care tips, you can maintain the integrity of your fiber optic infrastructure and avoid costly repairs or replacements.

Gentle Handling

When working with fiber optic cables, it’s important to handle them gently and avoid applying excessive force or pressure. Rough handling can cause physical damage, such as microbends or fiber breakage, which can lead to signal loss or degradation. Treat fiber optic cables with care to ensure their longevity and performance.

Minimum Bend Radius

Adhering to the minimum bend radius is crucial to prevent fiber breakage and signal loss. Each type of fiber optic cable has a specific minimum bend radius specified by the manufacturer. Avoid bending the cable beyond this radius, as it can cause permanent damage to the fiber and affect the quality of the transmission. Always follow the cable’s specifications and guidelines for bending to maintain optimal performance.

Connector Cleanliness

Keeping connectors clean is essential for maintaining the integrity of the optical signal. Dust, dirt, and debris can accumulate on connectors and hinder the transmission of light, leading to signal loss or degradation. Regularly inspect and clean connectors using lint-free wipes or appropriate cleaning tools to ensure optimal performance. Follow industry best practices and guidelines for connector cleaning.

“Clean connectors are essential for reliable connections and optimal signal transmission.”

Gloves and Eye Protection

When working with fiber optic cables, always wear gloves and eye protection to ensure personal safety. Gloves protect the cables from oil, dirt, and moisture on your hands, which can affect their performance and longevity. Eye protection, such as safety glasses or goggles, safeguards your eyes from potential hazards, such as fiber shards or chemicals used in the installation or maintenance process. Prioritize safety by wearing appropriate protective gear.

Proper handling and care of fiber optic cables are paramount to ensure their optimal performance and longevity. By practicing gentle handling, adhering to the minimum bend radius, maintaining connector cleanliness, and wearing gloves and eye protection, you can safeguard your fiber optic infrastructure and achieve reliable high-speed connectivity.

Regular Testing and Maintenance

To ensure the optimal performance and reliability of your fiber optic network, regular testing and maintenance are imperative. By employing the right tools and techniques, you can identify any potential issues and take proactive measures to maintain the network’s functionality. Here are some key areas to focus on:

- Attenuation Measurement: Utilize optical power meters to measure the attenuation of the fiber optic cables. This helps you assess signal loss and identify any factors that may be affecting the transmission quality.

- Dispersion Measurement: Use tools like OTDR (Optical Time-Domain Reflectometer) to measure dispersion, specifically chromatic dispersion and modal dispersion. This aids in evaluating the fiber optic cables’ ability to transmit data accurately over long distances.

- Reflection Measurement: Assess reflections within the network using devices such as visual fault locators. Minimizing reflections is crucial to reducing signal loss and enhancing network performance.

Comparing the results of these measurements with baseline values allows you to detect any deviations or anomalies that may indicate potential issues. By addressing these concerns promptly, you can avoid network disruptions and maintain the reliability of your fiber optic network.

Regular maintenance and testing are key to the long-term functionality of your fiber optic network.

Maintenance Best Practices

In addition to regular testing, the following maintenance tips will help ensure the longevity and reliability of your fiber optic network:

- Inspect and Clean Connectors: Regularly inspect and clean fiber optic connectors to remove any dirt, dust, or contaminants. Clean connectors ensure optimal signal transmission and prevent signal loss.

- Monitor Cable Integrity: Regularly check for any signs of cable damage, such as cuts, kinks, or bends beyond the acceptable radius. Address these issues promptly to prevent further damage and degradation of signal quality.

- Perform Visual Inspections: Conduct visual inspections of the fiber optic cables and connectors to identify any visible defects or abnormalities. This allows for early detection and timely repairs.

Implementing these maintenance best practices, along with regular testing, will help safeguard the reliability and performance of your fiber optic network. By staying proactive and promptly addressing any issues, you can ensure uninterrupted connectivity and optimize the efficiency of your network.

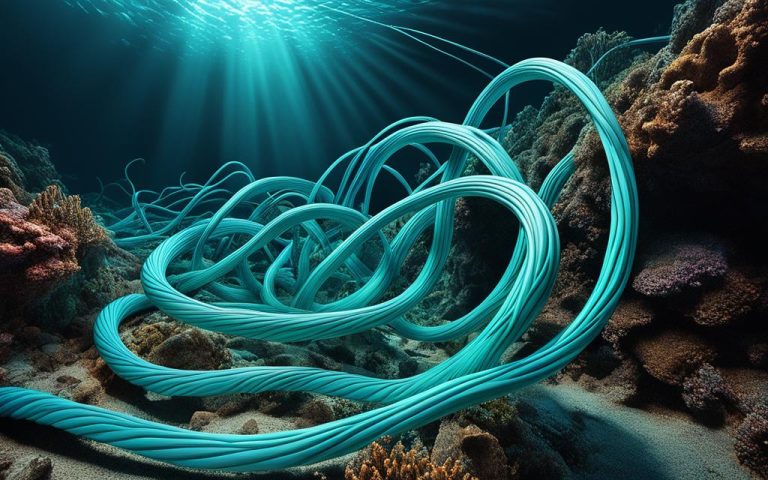

Proper Storage and Environmental Considerations

Proper storage plays a critical role in protecting fiber optic cables from potential damage caused by dust, moisture, and other environmental factors. By implementing the following best practices, you can ensure the longevity and reliability of your fiber optic infrastructure:

- Dust Protection: Use dust caps to cover connectors, safeguarding them from dust accumulation and preventing contamination that can degrade optical performance.

- Moisture Protection: Store cables in a cool, dry location to avoid moisture-related issues. Moisture can cause corrosion and lead to signal loss or degradation.

- Temperature Control: Keep fiber optic cables away from heat sources and chemicals, as extreme temperatures can impact their integrity and functionality. Maintain a stable temperature environment for optimal performance.

- Cable Coiling: When storing cables, ensure they are loosely coiled to avoid kinks and twists. Excessive tension or sharp bends can damage the fibers, affecting signal quality and transmission.

- Cable Storage Location: Choose a dedicated storage area that is clean, well-ventilated, and free from heavy foot traffic. Store cables in racks or cabinets to minimize the risk of accidental damage or disorganization.

“Proper storage and environmental control are essential for preserving the performance and longevity of fiber optic cables.”

Creating an ideal storage environment for your fiber optic cables is crucial for maintaining their integrity and extending their lifespan. By following these guidelines, you can protect your investment and ensure reliable connectivity in your optical fiber network.

Conclusion

Proper optical fiber installation and maintenance are crucial for achieving high-speed connectivity and reliable performance in fiber optic networks. By following the best practices outlined in this guide, including accurate cable measurement, adherence to cable ratings, gentle handling, regular testing, and proper storage, you can ensure the longevity and optimal functioning of your fiber optic infrastructure.

Taking the time to implement these guidelines will help maximize your investment and provide seamless connectivity for your organization or business. By maintaining your fiber optic network according to the recommended maintenance procedures, you can enjoy the benefits of high-speed data transmission, reliable performance, and improved efficiency.

Remember, regular testing and evaluation are essential to identifying and addressing any issues or anomalies that may arise over time. With proper maintenance, your fiber optic network can continue to deliver fast and reliable connectivity, supporting your organization’s growth and success.

FAQ

What is the importance of accurately determining the required cable length?

Accurately determining the required cable length ensures that you have enough cable to cover the entire facility, including corners, vertical installations, and non-linear connections. Ordering extra lengths also provides slack for flexibility and future modifications.

What is a port map and why is it important during installation?

A port map is a detailed plan that specifies the name of each port, its connection, and the location of network cabinets and patch panels. It helps ensure efficient installation and easy reference for future maintenance.

How should I handle fiber optic cables to prevent damage?

Fiber optic cables should be handled gently without applying excessive force or pressure. It is important to adhere to the minimum bend radius to prevent fiber breakage. Additionally, avoid touching the connector end face with fingers or sharp objects to prevent scratches or chips.

What tools can I use to test fiber optic cables?

Tools such as optical power meters, OTDRs (Optical Time Domain Reflectometers), and visual fault locators are commonly used to measure parameters like attenuation, dispersion, and reflection in fiber optic cables.

How should I store fiber optic cables to protect them?

To protect fiber optic cables from dust, moisture, and environmental factors, use dust caps to cover connectors and store them in a cool, dry place away from heat sources and chemicals. Coiling the cables loosely also helps avoid kinks and damage.

Why is regular testing and maintenance important for fiber optic cables?

Regular testing and maintenance are crucial to maintain the optimal performance and reliability of fiber optic cables. By comparing test results with baseline values, any issues or anomalies can be identified and addressed promptly.

What are the best practices for optical fiber installation and maintenance?

The best practices for optical fiber installation and maintenance include accurately determining cable length, creating a detailed port map, adhering to cable ratings, handling cables gently, regularly testing cables, and storing them in a proper environment.