Troubleshooting common issues in optical networks is essential to ensure seamless connectivity and optimal performance. As fiber optic networks become increasingly prevalent in various industries, it is crucial for network administrators and technicians to be well-versed in identifying and resolving common issues that may arise.

Optical networks can experience connectivity issues due to various factors, such as signal loss, interference, or faulty components. By understanding the fundamentals of fiber optic technology and the installation processes involved, network professionals can effectively troubleshoot and rectify these issues, ensuring the longevity and efficiency of the network.

In the following sections, we will delve into the details of fiber optic networks, their installation and termination processes, common issues faced during troubleshooting, effective techniques for identifying faults, and repairing optical fiber network faults. By following these comprehensive guidelines, you will be equipped with the knowledge and tools to tackle any connectivity issues that may arise in optical networks.

Understanding Fiber Optic Networks

Fiber optic networks revolutionize data transmission by utilizing thin strands of glass or plastic, known as optical fibers, to transmit data through light pulses. These networks offer numerous advantages over traditional copper cables, including:

- High bandwidth

- Fast signal transmission

- Minimal signal loss

- Resistance to electromagnetic interference (EMI)

- Enhanced security

Fiber optic cables consist of multiple optical fibers bundled together and surrounded by a protective cladding and an outer jacket. This design ensures the integrity and longevity of the fibers, allowing for reliable and efficient data transmission.

Understanding the intricacies of fiber optic networks, including their design and components, is crucial for troubleshooting and maintaining optimal performance. By possessing a comprehensive knowledge of fiber optic networks, network administrators and technicians can swiftly identify and rectify issues, ensuring the seamless transmission of data.

Advantages of Fiber Optic Networks

“Fiber optics offers higher bandwidth and faster speeds compared to traditional copper cables, making it ideal for modern technology-driven applications.” – John Smith, Networking Expert

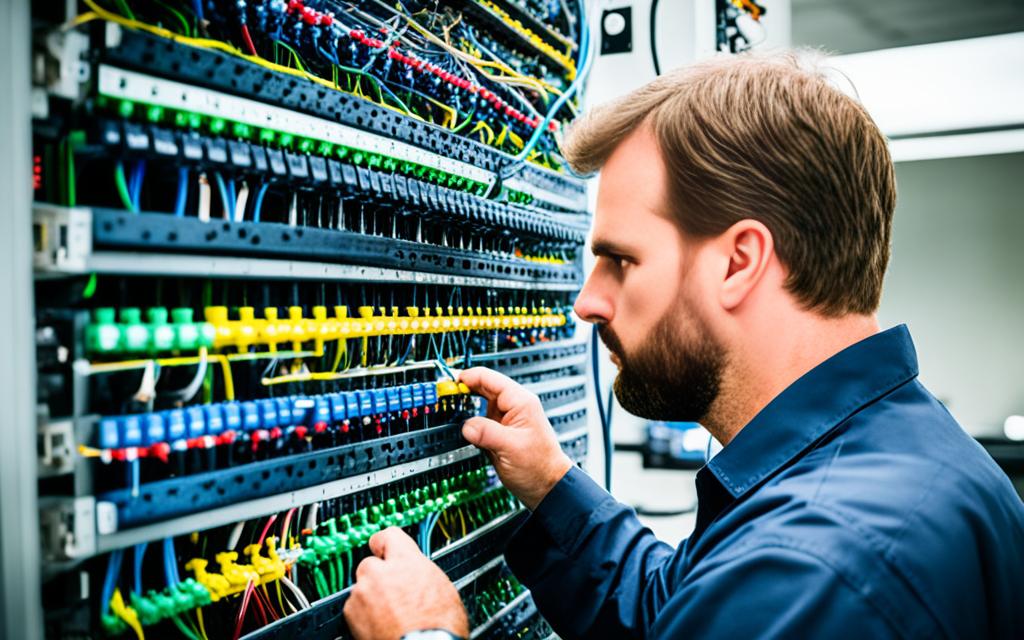

Installation and Termination of Fiber Optic Networks

The installation process of fiber optic networks involves careful planning, design, and implementation to ensure optimal performance. Here is an overview of the installation process and the termination of fiber optic links:

Installation Process

1. Planning and Design: Before installing a fiber optic network, thorough planning is essential. This includes assessing the network requirements, determining the appropriate fiber type, and selecting the right cable construction. Factors such as the environment and distance between nodes should also be considered.

2. Cable Installation: During the installation, it is crucial to follow proper guidelines to prevent fiber damage and maintain network integrity. Adhering to the bending radius and tension limits helps protect the fibers from stress and potential breakages.

3. Testing and Verification: After the installation is complete, it is vital to test the performance of the fiber optic link. Testing ensures that the installation meets the required specifications and identifies any potential issues that may need to be addressed.

Termination of Fiber Optic Links

Fiber optic links can be terminated using two main methods: mechanical splicing and fusion splicing.

- Mechanical Splicing: This method involves aligning and joining the fibers using mechanical connectors. It offers ease of installation and reusability, making it suitable for temporary setups or situations where frequent changes are required.

- Fusion Splicing: Fusion splicing involves permanently fusing the fiber ends together using heat. This method provides a low-loss and highly reliable connection, ensuring minimal insertion loss and back reflection.

Fiber patch cords are used to connect the terminated fibers to networking equipment, enabling seamless data transmission.

Testing plays a crucial role in the installation and termination process. It helps validate the connectivity, identify any potential issues, and ensure optimal performance.

Comparison of Mechanical Splicing and Fusion Splicing

| Criteria | Mechanical Splicing | Fusion Splicing |

|---|---|---|

| Installation Time | Quick | Time-consuming |

| Insertion Loss | Higher | Lower |

| Back Reflection | Higher | Lower |

| Reliability | Lower | Higher |

Having completed the installation and termination steps correctly, the fiber optic network is now ready for operation, providing reliable and efficient connectivity.

Common Issues in Fiber Optic Troubleshooting

Inaccurate test results in fiber optic troubleshooting can be caused by various factors, including dirty connectors, incorrect test settings, or faulty equipment. One of the most common issues is dirty connectors, which can lead to attenuation and reflection problems. It is essential to regularly clean connectors and adapters before testing to ensure accurate results and optimal performance. Proper cleaning techniques using lint-free wipes and approved cleaning solutions can remove contaminants and maintain the integrity of the connection.

Another common issue is high optical power loss, which is often caused by fiber breaks or damage. Fiber optic cables are delicate and should be handled with care and protected from excessive bending, pulling, or crushing. These precautionary measures can prevent high power loss and maintain the signal quality. Additionally, it is important to ensure compatibility between equipment to avoid compatibility issues that can impact the performance of the optical network.

During troubleshooting, cable or strand swaps can inadvertently occur, leading to connectivity issues and signal loss. Careful attention must be given to cable management to avoid any confusion or misconfiguration. Environmental factors such as temperature, humidity, and dust can also affect the performance of fiber optic networks. Maintaining appropriate environmental conditions and implementing proper cable management practices can help mitigate these issues.

“Regular cleaning of connectors and adapters, careful handling of fiber optic cables, and ensuring compatibility between equipment are crucial steps in fiber optic troubleshooting.”

In conclusion, fiber optic troubleshooting requires thorough attention to detail and adherence to best practices. By addressing common issues such as dirty connectors, high optical power loss, cable/strand swaps, compatibility issues, and environmental factors, network administrators and technicians can effectively diagnose and resolve problems in fiber optic networks.

Troubleshooting Techniques for Optical Networks

Troubleshooting techniques for optical networks require the use of specialized tools and equipment to identify and isolate faults effectively. By employing the following techniques, network administrators and technicians can diagnose and repair issues in optical fiber networks.

1. Optical Power Meters:

Optical power meters are essential tools for measuring the power levels of optical signals in fiber optic networks. These meters help identify if the received power falls within the recommended operating range, allowing technicians to pinpoint power-related issues.

2. Optical Time-Domain Reflectometers (OTDR):

An OTDR is a crucial tool for troubleshooting fiber optic networks. It sends light pulses through the fiber and analyzes the reflected signals, providing information about signal loss, breakages, or other anomalies. OTDRs help locate faults accurately, making them indispensable for network maintenance and repairs.

3. Light Sources:

Light sources generate stable light signals that can be used to test individual components of optical networks. By sending light through fibers and observing the received signal, technicians can assess the quality of the connections and identify any discrepancies.

4. Power Meters:

Power meters are used to measure the optical power levels in fiber optic networks. They assist in identifying power losses, mismatches, or inconsistencies in optical links. Technicians can compare the power levels at different points in the network to pinpoint the source of the problem.

5. Cleaning Connectors:

One of the most common causes of signal degradation is dirty fiber optic connectors. Regularly cleaning connectors with lint-free wipes and appropriate solvents can help maintain optimal signal integrity and prevent connectivity issues.

6. Verifying Test Settings:

Technicians should ensure that the test settings on the equipment used for troubleshooting optical networks are correct. Incorrect settings can lead to inaccurate results and misinterpretation of network issues. Verifying and adjusting test settings as necessary is vital for accurate troubleshooting.

7. Inspecting Cables for Damage:

Visual inspection of fiber optic cables is essential for detecting any physical damage that may affect network performance. Technicians should look for cuts, kinks, bends exceeding the recommended limits, or other signs of wear and tear. Identifying and replacing damaged cables can help restore connectivity and prevent further issues.

8. Calibrating Equipment:

Regular calibration of testing equipment is crucial for accurate measurements and reliable troubleshooting. By ensuring that equipment is calibrated to industry standards, technicians can trust the test results and make informed decisions regarding network repairs.

Utilizing these troubleshooting techniques, network professionals can efficiently diagnose and resolve issues in optical fiber networks, ensuring uninterrupted connectivity and optimal performance.

Repairing Optical Fiber Network Faults

When it comes to repairing faults in optical fiber networks, having the right tools is crucial. The use of fiber splicers, cleavers, connectors, and patch cords can make all the difference in restoring network functionality quickly and efficiently.

Fiber splicers are essential for repairing breaks or cuts in fiber optic cables. These devices enable the fusion of two fiber ends, ensuring a seamless connection and the restoration of data transmission. Fiber splicers play a vital role in maintaining the integrity and performance of the network.

Cleavers are another tool that aids in the repair process. These devices ensure precise and smooth cuts on fiber ends, facilitating proper fusion and reducing signal loss. By creating a clean and well-prepared surface, cleavers enhance the overall quality and reliability of the repair.

Fiber connectors provide the mechanical and optical interfaces between fibers and devices. These connectors are designed to seamlessly join fibers, maintaining signal integrity and connectivity. They play a crucial role in repairing faults and ensuring the seamless flow of data through the network.

Patch cords are commonly used to extend, bridge, or bypass fibers during the repair process. These cords enable technicians to connect and disconnect fibers without compromising the overall network structure. Patch cords are invaluable assets in troubleshooting and repairing fiber segments efficiently.

In summary, the use of fiber splicers, cleavers, connectors, and patch cords is essential for repairing faults in optical fiber networks. These tools enable technicians to efficiently address breaks, cuts, and other issues, ensuring the seamless transmission of data and the overall performance of the network.

| Tool | Function |

|---|---|

| Fiber Splicer | Fuse two fiber ends together |

| Cleaver | Ensure precise and smooth cuts on fiber ends |

| Fiber Connector | Provide mechanical and optical interfaces between fibers and devices |

| Patch Cord | Extend, bridge, or bypass fibers during repairs |

Conclusion

Troubleshooting fiber optic networks requires a systematic approach to effectively identify and resolve issues. By following the steps of identifying the problem, isolating the fault, repairing the fault, and verifying the solution, network administrators and technicians can ensure the optimal performance and reliability of optical fiber networks.

One crucial aspect of troubleshooting is gathering information about the network. This includes understanding the network’s design, installation processes, and the components involved. Armed with this knowledge, technicians can utilize specialized tools for testing and measuring optical parameters. Optical power meters, optical time-domain reflectometers (OTDR), and light sources are just a few examples of the tools that play an essential role in pinpointing faults and diagnosing connectivity issues.

Repairing faults in fiber optic networks requires the use of appropriate tools such as fiber splicers, cleavers, and connectors. Proper techniques, including cleaning connectors, inspecting cables for damage, and calibrating equipment, are vital to ensuring successful repairs. By adhering to these practices, technicians can not only effectively troubleshoot and repair fiber optic networks but also prevent future issues that may impact their performance.

FAQ

Why is troubleshooting common issues in optical networks important?

Troubleshooting common issues in optical networks is important for maintaining and repairing fiber optic systems. It helps ensure the longevity and efficiency of fiber optic networks by identifying and resolving connectivity issues.

What are fiber optic networks?

Fiber optic networks utilize thin strands of glass or plastic called optical fibers to transmit data through light pulses. They offer high bandwidth, fast signal transmission, minimal signal loss, resistance to electromagnetic interference (EMI), and enhanced security compared to traditional copper cables.

What is the installation and termination process of fiber optic networks?

The installation process of fiber optic networks involves proper planning and design, selecting the appropriate fiber type and cable construction, and considering factors such as the environment and distance between nodes. The termination of fiber optic links can be done through mechanical splicing or fusion splicing, ensuring low insertion loss and minimal back reflection.

What are some common issues in fiber optic troubleshooting?

Common issues in fiber optic troubleshooting include dirty connectors, incorrect test settings, faulty equipment, high optical power loss, compatibility issues between equipment, cable/strand swaps, and issues related to environmental factors.

What techniques are used for troubleshooting optical networks?

Troubleshooting techniques for optical networks involve using specialized tools and equipment such as optical power meters, optical time-domain reflectometers (OTDR), light sources, and power meters. Techniques like cleaning connectors, verifying test settings, inspecting cables for damage, and calibrating equipment can help identify and isolate faults.

How can faults in optical fiber networks be repaired?

Repairing faults in optical fiber networks requires the use of appropriate tools like fiber splicers, cleavers, connectors, and patch cords. Fiber splicers are used to fuse two fiber ends together to repair breaks or cuts. Cleavers ensure precise and smooth cuts on fiber ends. Fiber connectors provide mechanical and optical interfaces between fibers and devices. Patch cords are used to extend, bridge, or bypass fibers.

What is the importance of troubleshooting fiber optic networks?

Troubleshooting fiber optic networks is crucial for maintaining their optimal performance and reliability. It allows network administrators and technicians to identify and resolve any issues that may arise, ensuring the continuous and efficient functioning of the network.